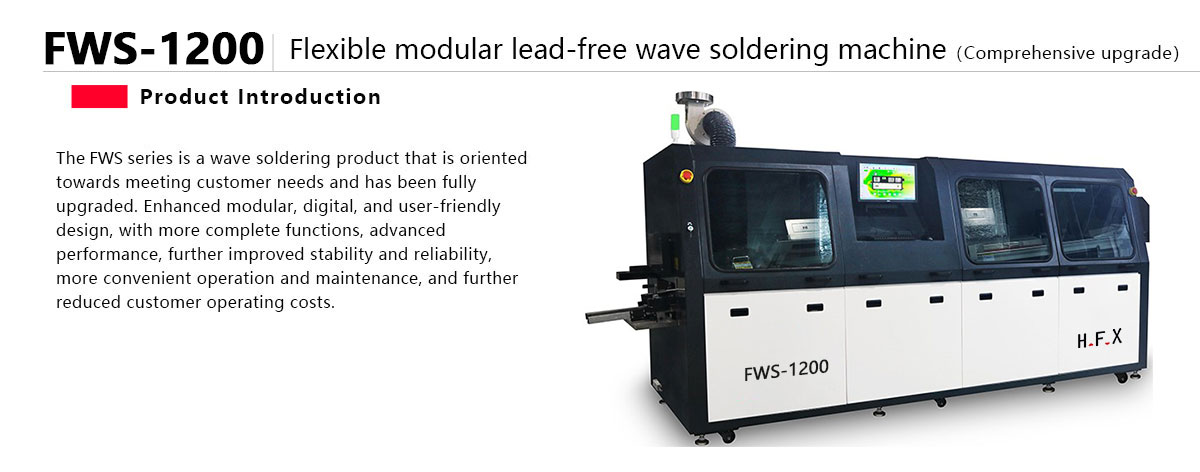

Characteristics of Wave Soldering FWS Series Products:

1. Transmission system: Direct connection plate structure, specially designed stainless steel chain transmission, unique design of aluminum alloy guide rail, durable and long-lasting; Transportation system: adopting a segmented floating structure to effectively prevent rail deformation;

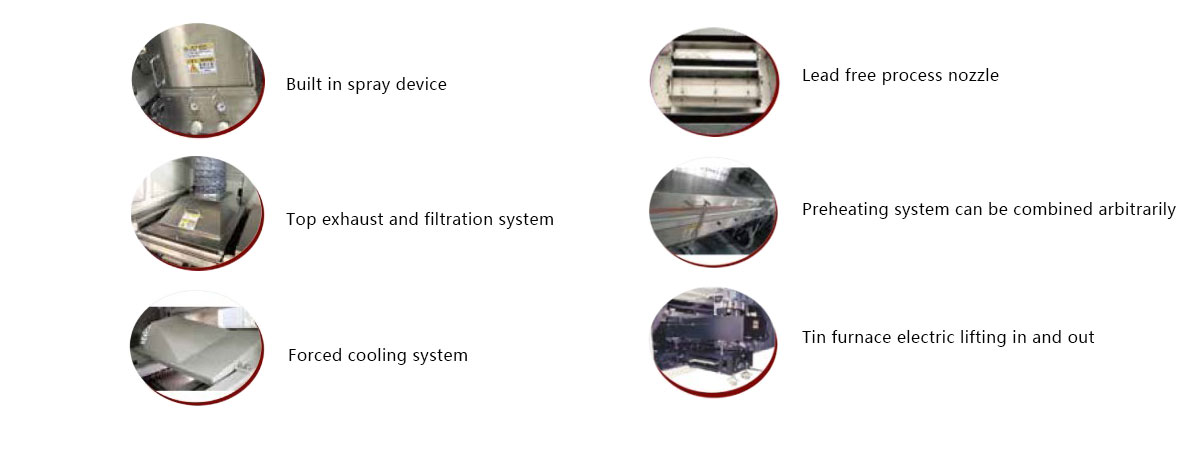

2. Preheating system: Adopting a drawer type modular energy-saving design, infrared and hot air can be combined arbitrarily, and PID temperature control is used to achieve a temperature control accuracy of ± 2 ℃. The temperature drop between the preheating zone and the welding zone is ≤ 5 ℃;

3. spray system: adopt precision control valve for digital regulation, which is convenient for management. The nozzle movement is controlled by a stepper motor. Automatic constant pressure supply of flux can make the spray flow quickly reach saturation, top air exhaust, filtering system;

4. The tin furnace adopts external heating, and the inner liner of the tin furnace is made of cast iron with anti-corrosion treatment on the inner surface. It is designed with two low flow nozzles and low oxidation capacity;

5. Forced cooling system, ensuring a cooling rate of 4-6 ℃/s (adjustable);

6. PC+PLC control system, Windows 7 operating system, Chinese/English operating interface, automatic storage function for process curves/data, and alarm for low or high flux liquid level; Low tin level alarm;

Product parameters:

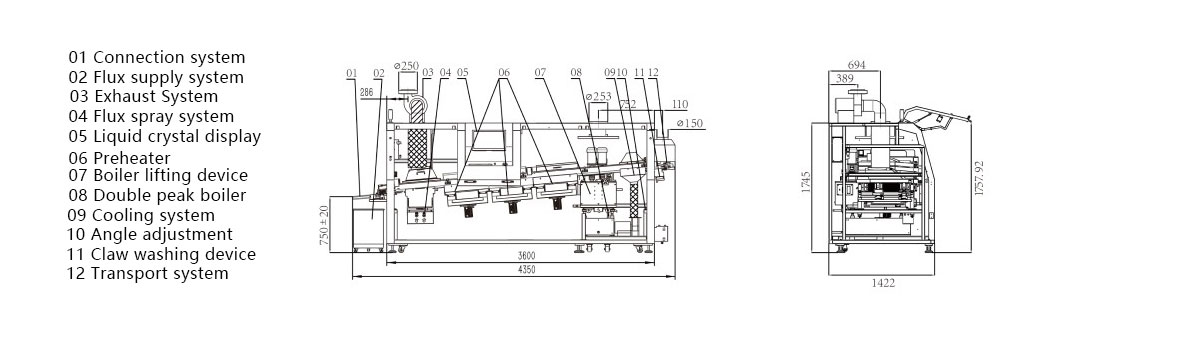

| Modol NO | FWS-1200 |

| Dimension:LxWxH(mm) | 4350×1422×1750 |

| Weigh | Approx.1600kg |

| Power Supply | 3PH 380V 50HZ(Customization supported) |

| Startup Power | 33KW |

| Operation Powr Consumption | 8KW |

| Control System | PC+PLC |

| Spraying movement | Step motor |

| Spray Pressure | 0.2Mpa~0.4Mpa |

| Flux Flow Arrange | option |

| Auto Fill Flux | Standards |

| Exhaust | Top exhaust |

| ExhaustDucting Diameter(mm) | Φ250 |

| Exhaust fan power | 750W |

| Preheating Mode | Convection / IR emitter |

| Control Mode | PID |

| Preheating Zone Number | 3 |

| Preheating Length(mm) | 1800 |

| Preheating Temperature | Room temperature~200℃ |

| Warm-upTime(min) | Appro×.12min(setting:150℃) |

| PCB Width(mm) | 50~350 |

| Convoyor Direction | L→R(Option:R→L) |

| Conveyor Speed(mm/min) | 500~1800 |

| Conveyor Height(mm) | 750±20 |

| Available Component Heigh (mm) | (Top)120,Bottom15 |

| Conveyor Speed Control Mode | Closed loop stepless speed regulationg Inverter |

| Fingers | Spring Pressing Finger/D-40Type Fingor/Double-hook Finger/Heavy type double hook f inger,Options |

| Conveyor Angle | 4~7° |

| Type of solder Pot | Motor drive |

| Solder Pot Material | Casting Iron |

| Wave Height Adjustment | Digital Control by PC |

| Cooling Method | Air Cooling Option:Water cooing |

| Heater Power | 13.5KW |

| Solder Pot Temperature | 300°℃ |

| Solder Pot Capacity | Approx.480KG |

| Wave Drive Power | 180W*2 3PH 220VAC |

| Solder Pot Warm-up Time | Approx.150min(setting:250℃) |

| Temperature Control Mode | PID |

| Finger Cleaning System | Brush |

> Equipment can be customized according to customer needs