Features of Wave Soldering HFS Series Products:

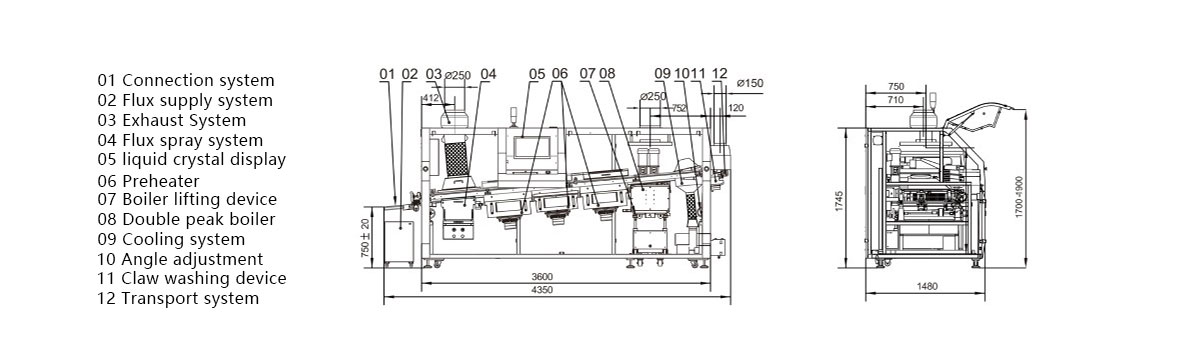

1. The transportation system adopts a segmented floating structure to effectively prevent guide rail deformation. The new titanium alloy double hook claw is non stick to tin and has a direct connection to the board. The aluminum guide rail makes the board entry smoother.

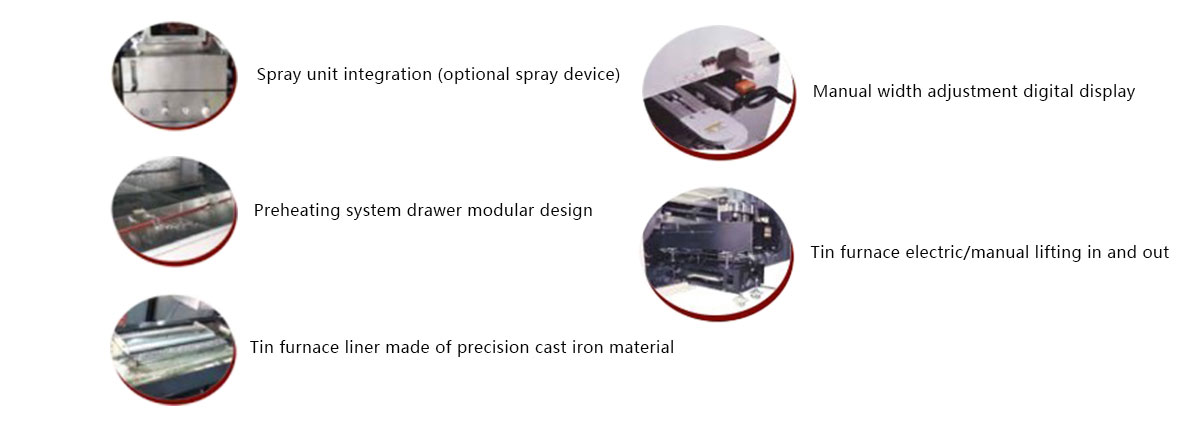

2. The integrated module design of spray unit is connected to the host through a quick connector. The nozzle adopts a new precision nozzle, which can achieve the coating effect of high efficiency and uniform atomization, and can meet the process requirements of aqueous flux.

3. The preheating system adopts a micro hot air+far-infrared heating tube method, three preheating temperature zones, drawer style modular design, and flexible selection of mixed preheating mode. The temperature is uniform and stable.

4. Forced natural air cooling system. (The chiller is an option)

5. Tin furnace system, with special materials used for the inner liner and anti-corrosion treatment on the inner surface. The new nozzle fixing method is convenient for loading and unloading; the automatic flow guide device is convenient for collecting tin slag, and the peak shape can be adjusted. The temperature control accuracy of the tin furnace is ± 2 ℃, and both the in and out, lifting and lowering of the tin furnace can be done manually and electrically, making it easy to operate.

6. Windows 7 operating system, intelligent software in Chinese/English, with parameter setting, saving, reuse, and remote monitoring functions. Process curve/data automatic storage function, temperature curve testing function.

Product parameters:

| Modol NO | HFS-1200 | HFS-1250 | HFS-1280 |

| Dimension:LxWxH(mm) | 4350*1480*1750 | 4350*1580*1750 | 4350*1740*1750 |

| Weigh | Approx.1800kg | Approx.1950kg | Approx.2150kg |

| Power Supply | 3PH 380V 50HZ | 3PH 380V 50HZ | 3PH 380V 50HZ |

| Startup Power | 32KW | 32KW | 45KW |

| Operation Powr Consumption | Approx.8KW | Approx.8.5kW | Approx.11KW |

| Control System | PC+PLC | PC+PLC | PC+PLC |

| Spraying movement | Step motor | Step motor | Step motor |

| Spray Pressure | 0.2Mpa-0.4Mpa | 0.2Mpa-0.4Mpa | 0.2Mpa-0.4Mpa |

| Flux Flow Arrange | Option | Option | Option |

| Auto Fill Flux | Standard | Standard | Standard |

| Exhaust | Top exhaust+Side exhaust | Top exhaust+Side exhaust | Top exhaust+Side exhaust |

| ExhaustDucting Diameter(mm) | Φ250 | Φ250 | Φ250 |

| Exhaust Capacity | 30m³/min | 30m³/min | 30m³/min |

| Preheating Mode | Hot air Convection / IR | Hot air Convection / IR | Hot air Convection / IR |

| Control Mode | PID | PID | PID |

| Preheating Zone Number | 3 | 3 | 3 |

| Preheating Length(mm) | 1800 | 1800 | 1800 |

| Preheating Temperature | Room temperature~200℃ | Room temperature~200℃ | Room temperature~200℃ |

| Warm-upTime(min) | Approx.12min(setting:150℃) | Approx.12min(setting:150℃) | Approx.12min(setting:150℃) |

| Blower Motor | 250W 3PH 220VAC | 250W 3PH 220VAC | 250W 3PH 220VAC |

| PCB Width(mm) | 50-350 | 50-450 | 50-610 |

| Convoyor Direction | L-R(Option:R-L) | L-+R(Option:R-L) | L-R(Option:R-L) |

| Conveyor Speed(mm/min) | 500~1800 | 500~1800 | 500-1800 |

| Conveyor Height(mm) | 750±20 | 750±20 | 750±20 |

| Available Component Heigh (mm) | Top 120(Option: 240) Bottom 15 | Top 120(Optn: 250) Bottom 15 | Top 120(Option: 250) Bottom 15 |

| Conveyor Speed Control Mode | Closef-loop stepless speed regulationg Inverter | Closef-loop stepless speed regulationg Inverter | Closef-loop stepless speed regulationg Inverter |

| Fingers | Spring Pressing Finger/D-40Type Fingor/Double-hook Finger/Heavy type double hook f inger,Options | Heavy type double hook f inger/ | |

| Opt on:Special jig for fixture | |||

| Conveyor Angle | 4-7° | 4-7° | 4-7° |

| Type of solder Pot | Motor drive | Motor drive | Motor drive |

| Solder Pot Material | Casting Iron | Casting Iron | Casting Iron |

| Wave Height Adjustment | Inverter Approx:Digital Control by PC | ||

| Cooling Method | Air Cooling Option:Watercooling | ||

| Heater Power | 13.5KW | 13.5KW | 18KW |

| Solder Pot Temperature | 300℃ | 300℃ | 300℃ |

| Solder Pot Capacity | Approx.480KG | Approx.550KG | Approx.640KG |

| Wave Drive Power | 180Wx23PH220VAC | 180W*23PH220VAC | 180Wx23PH220VAC |

| Solder Pot Warm-up Time | Approx.150min(setting:250℃) | Approx.150min(setting:250℃) | Approx.150min(setting:250℃) |

| Temperature Control Mode | PID | PID | PID |

| Finger Cleaning System | Brush | Brush | Brush |

> Customization can be made according to customer needs.