Efficient DIP production line solution

The H.F.X DIP production line is a comprehensive SMT/DIP system designed to facilitate seamless PCB insertion and assembly. It integrates both manual and automated options, enabling precise handling of Through-Hole Technology (THT) tasks. Key components include a DIP inserter for component insertion, a wave loader for smooth entry, a wave unloader for safe exit, and an assembly belt line for final inspection.

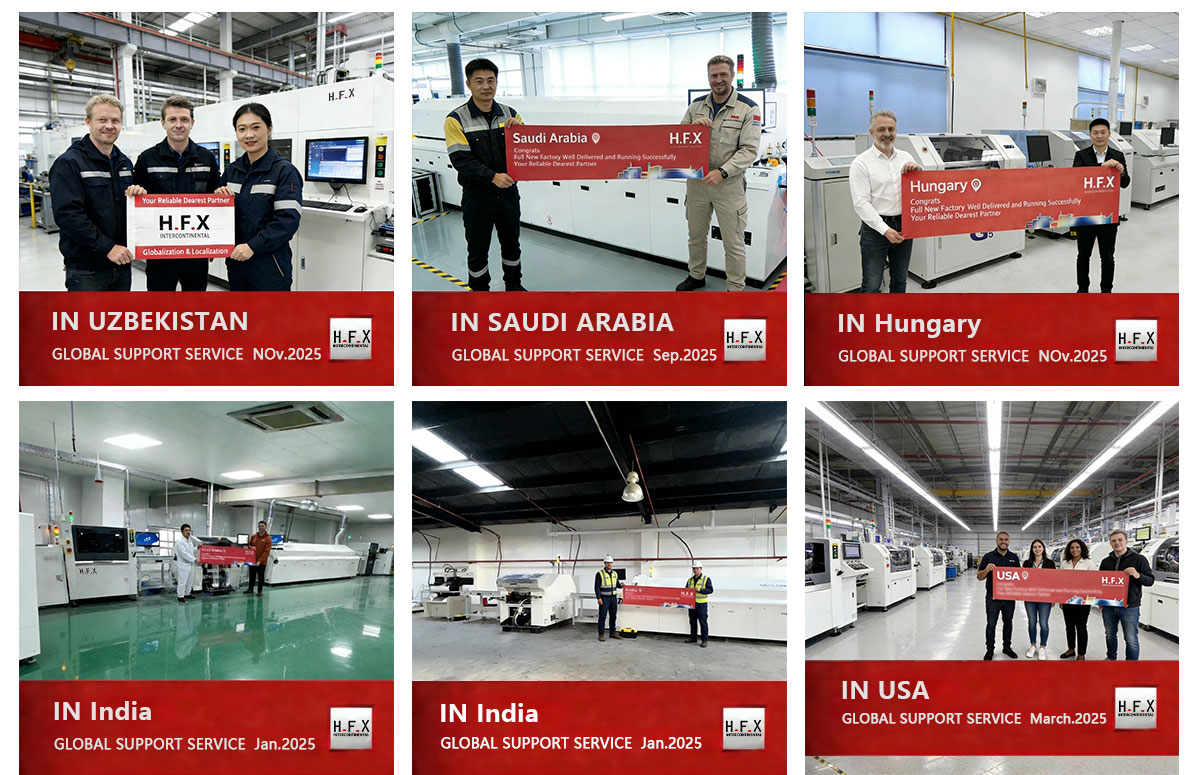

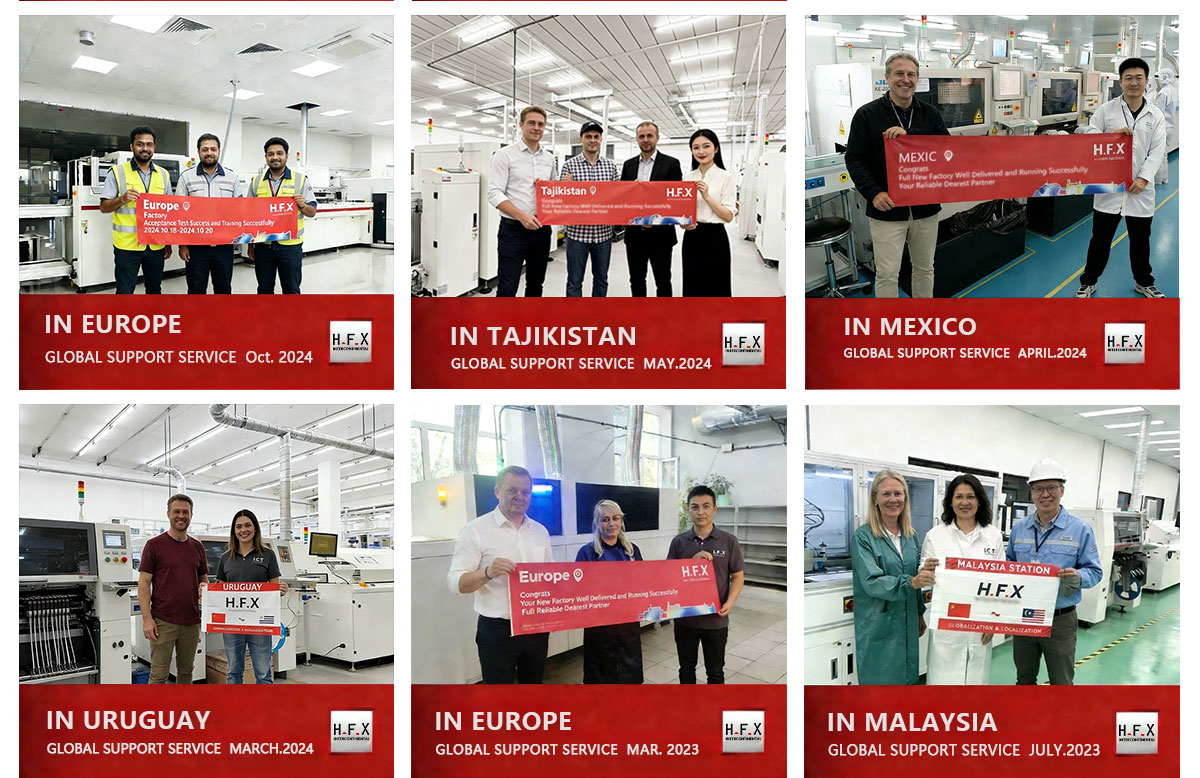

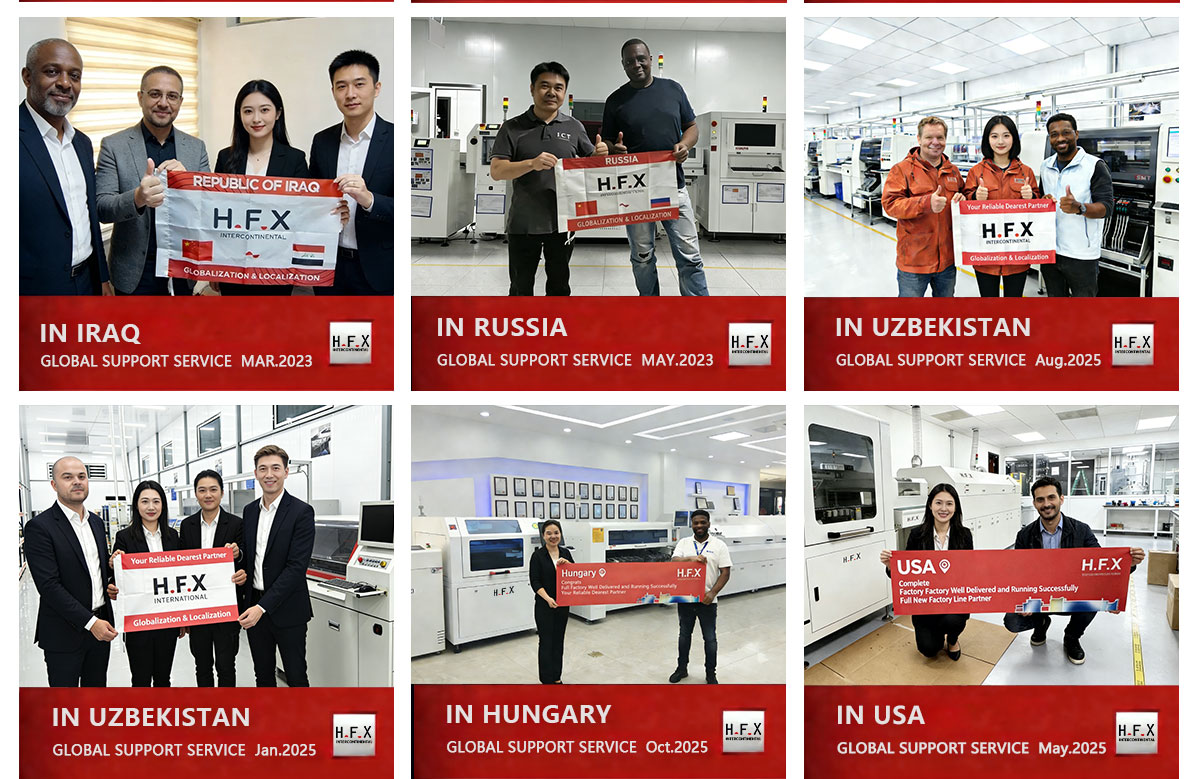

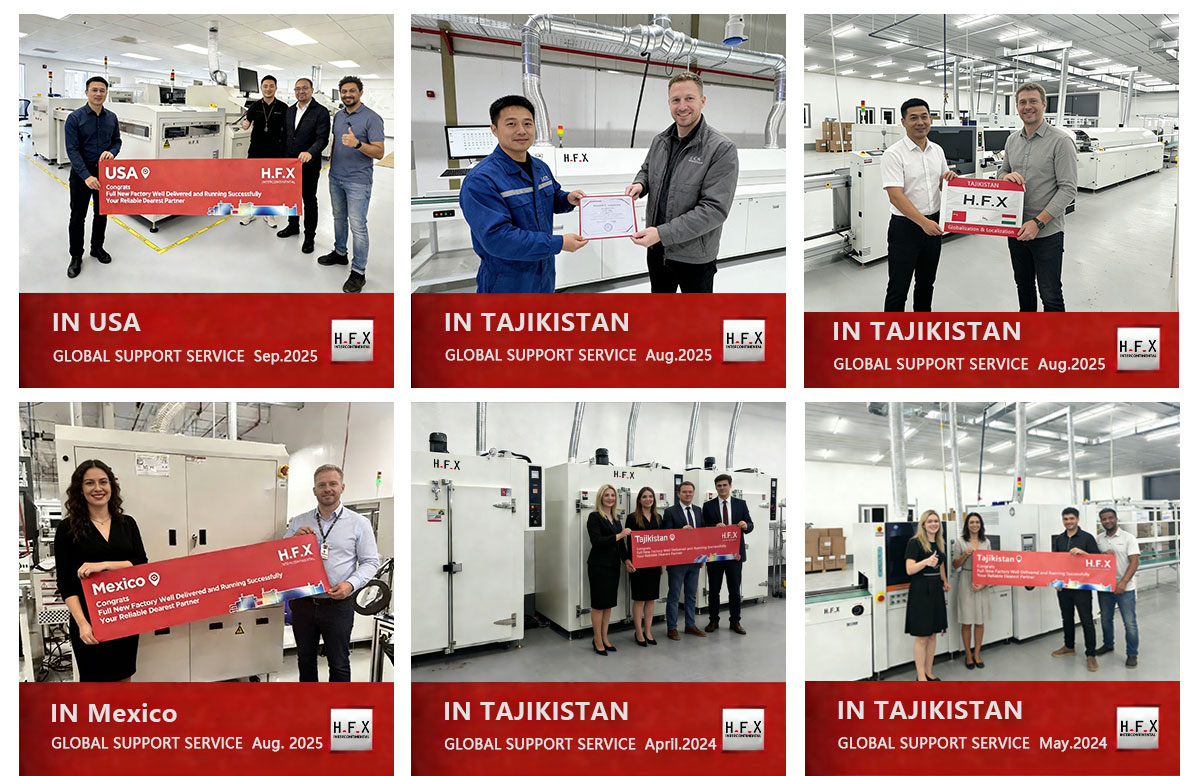

Utilizing a sturdy aluminum alloy frame and Taiwanese motors, it supports PCB sizes ranging from 50 to 350 millimeters, with a maximum speed of up to 5 meters per minute. This line can shorten production time while ensuring quality. H.F.X provides one-stop support from planning to optimization, assisting over 1,000 customers in more than 70 countries in building efficient factories. With over 12 years of experience, we specialize in simple and reliable tools that grow with your needs.

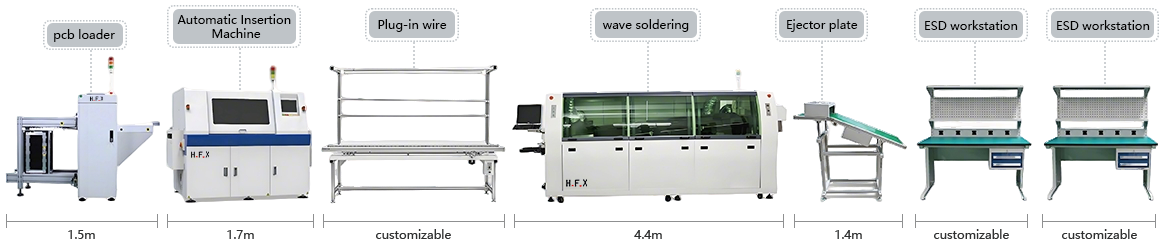

List of DIP circuit devices

Our DIP production line provides advanced tools to facilitate efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for precise component placement, a wave plate loader for smooth entry into the PCB, a wave unloader for safe exit, and an assembly belt line for final inspection. This high-quality PCB double-layer printing production line ensures stable operation, reliable THT insertion, and efficient assembly, meeting the diverse needs of the industry. Through modular design and H.F.X's global support, it enhances the productivity of plug-in operations.

DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Product Name | Purpose in DIP Line |

| Automatic Insert Machine | Automatically places components onto PCBs with precision for DIP production line. |

| Wave Soldering Machine | Melts solder to form solid joints on PCBs during THT plug-in process. |

| Selective Soldering Machine | Applies solder selectively to specific areas for accurate THT assembly |

| Post-wave Inline AOI | Inspects solder joints and placement defects on DIP assembled PCB. |

| X-ray inspection machine | Checks internal solder quality and hidden defects in THT components. |

| H.F.X Tester | Tests electrical performance and connectivity of assembled PCB. |

| Belt Assembly Line | Transports PCBs smoothly through the DIP line for efficient assembly and inspection. |

Certifications and Standards

H.F.X boasts top certifications such as CE safety certification, RoHS environmental material certification, and strict quality management ISO9001. We also hold patents for modular DIP design and automatic insertion technology, demonstrating innovation. These ensure that every production line meets global standards, from anti-static belts to motor control systems. Regular audits ensure that our 20,000 square meter factory complies with regulations, providing you with peace of mind. Customers rely on it for defect-free printed circuit boards and smooth exports. Our badge dates back to over 12 years of trust, focusing on simple and safe solutions.