Introduction

H.F.X UV oven is cost-effective drying Oven produced by H.F.X, mainly to deal with the application of Adhesive(glue,uv photosensitive, inks,Epoxy resin adhesive etc). then followed by injection-type or print multiple materials in an instant surface cured and dried.

Features

1. PLC+touch screen control, with independent temperature controller alarm and dual over temperature protection;

2. Stainless steel chain conveyor with an effective width of 50-450mm, electrically adjustable width, and conveying speed regulated by a speed controller;

3. Hand cranked lamp tube lifting method, electric lifting and lid opening function;

4. The device also carries one set of electronic dimming light sources, and the UV intensity can be quickly adjusted.

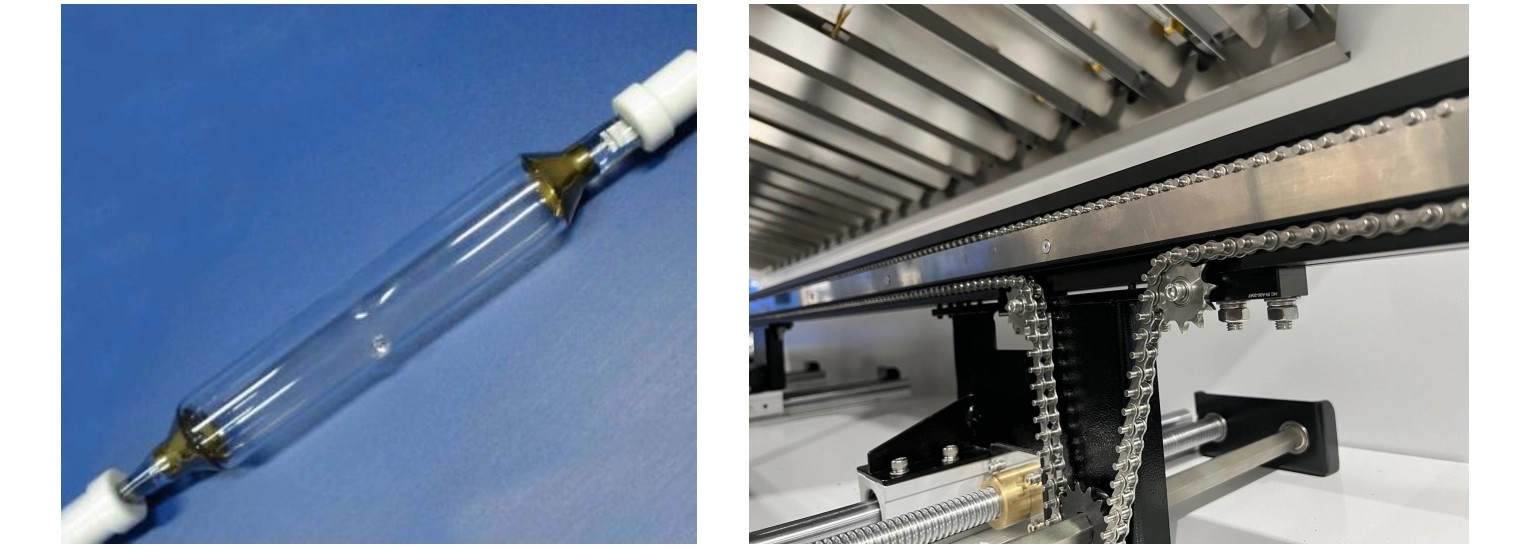

UV light:Imported material, stable performance, UV curing application, LED lamp optional.

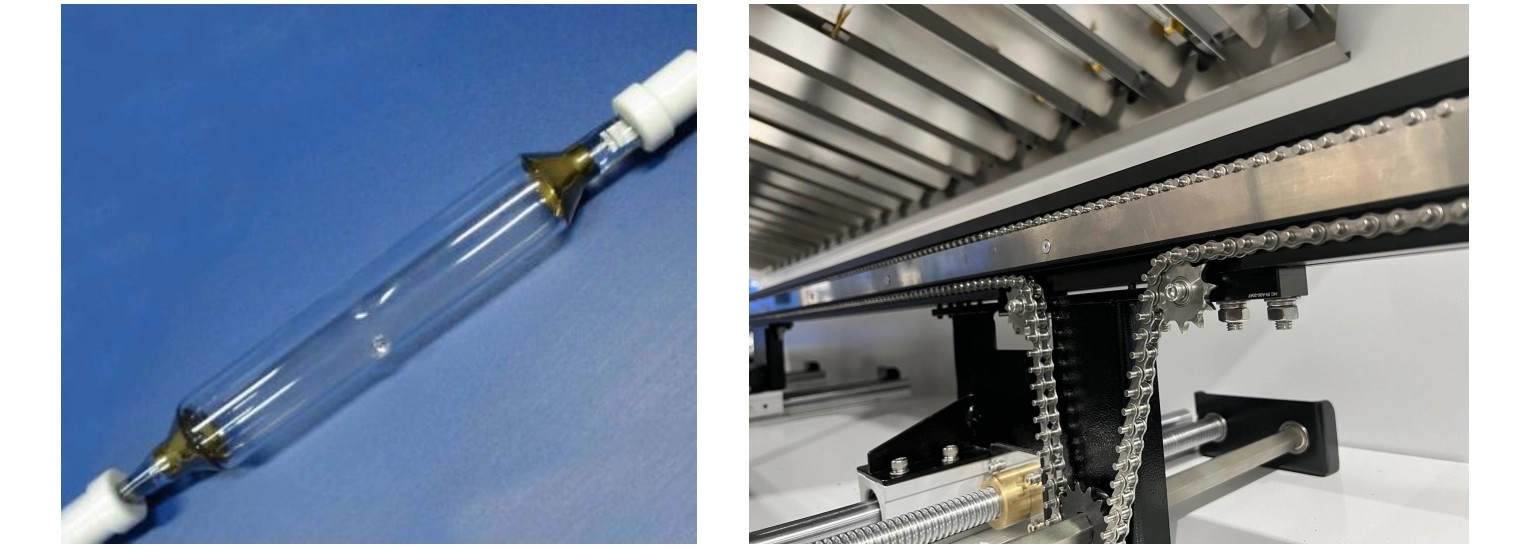

Transport system:The unique belt conveyor system can effectively prevent stuck PCB. The motor controls the speed and the stop position is precise. PCB entry and exit directions are freely available.

Technical Specifications

| Overall dimensions L*W*H | L1500mm*W1080mm*H1500mm |

| Control method | PLC+touch screen control |

| PCB transfer height | 910±20mm |

| Delivery method | Customized hard and hard aluminum alloy track+stainless steel chain (5mm extension pin) |

| Track length | 1500mm, customizable |

| Track bearing capacity | Supported by stainless steel wear-resistant strips, specially treated, with an even distribution of 5KG/m |

| Transport speed | Touch screen adjustment, 0-3.5m/min |

| Transmission direction | L→R(R→L) |

| Orbit adjustment width | MAX450mm |

| Lamp tube amplitude modulation mode | Hand-crank adjustment |

| Number of UV light sources | Group 1 |

| UV light source power | 6KW/set |

| Types of UV light sources | Mercury lamp light source |

| Lamp replacement cycle | 800-1500H |

| Effective irradiation range | 450mm |

| Equipment ventilation | 3 φ150 air vents to achieve optimal temperature control inside the furnace |

| Displacement requirements | 900 cubic meters/h |

| PCB board size | MAXW450*L450 |

Height of PCB components passing through the board | MAX:±110mm |

| Equipment weight | Approx.380KG |

| Power supply | AC380V, 50Hz (customizable) |

| Total power | 7KW |

> Equipment can be customized according to customer needs

FAQ:

1.Will you provide on-site support?

Our team of qualified and experienced engineers can provide on-site maintenance and repair support. You can use the online chat box Skype、Whatsapp、 Contact us by phone and email, and we are always on standby to assist you in resolving any issues.

2.Will any training be provided?

We provide a complete training program for all industrial testing equipment, maintenance equipment, picking and placing equipment, reflow soldering equipment, wave soldering, selective soldering equipment, solder paste printing machines, PCB splitting machines and other SMT production line equipment in our Shenzhen factory, and offer on-site training at the customer's location. Our plan aims to provide your engineers, technicians, and machine operators with the necessary knowledge to fully utilize the operation and maintenance of our machines.

3.Where can I buy spare parts?

You can visit our spare parts store to obtain the parts you need, which can be paid by bank transfer/PayPal/credit card. In addition, you can contact us to obtain parts and make payment through bank transfer.

H.F.X - Our Company

About H.F.X:

H.F.X is a leading provider of factory planning solutions and industrial inspection solutions. We have 4 wholly-owned factories that provide professional consulting and services to global customers. We have over 12 years of experience in electronic integrated solutions and industrial testing solutions. We not only provide a complete set of equipment, but also offer comprehensive technical support and services, and provide customers with more reasonable professional advice. We help many clients establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We will establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We have also obtained strict industry certifications such as CE, FDA, AERB, etc. Our products are exported to countries such as the United States, Germany, India, Singapore, Vietnam, Thailand, Canada, the United Kingdom, France, Italy, the Netherlands, Sweden, Mexico, Brazil, etc. We are trustworthy.

Exhibition:

For SMT factory setup and industrial non-destructive testing, we can provide you with:

1. We provide you with complete SMT solutions and industrial testing solutions

2. We Provide Core Technology With Our Equipments

3. We provide the most professional technical services

4. We have rich experience in establishing SMT factories and industrial testing

5. We can solve any problems related to SMT and industrial testing

UV Curing Oven Drying Oven UV-106