Fully Automated SMT Production Line Solution

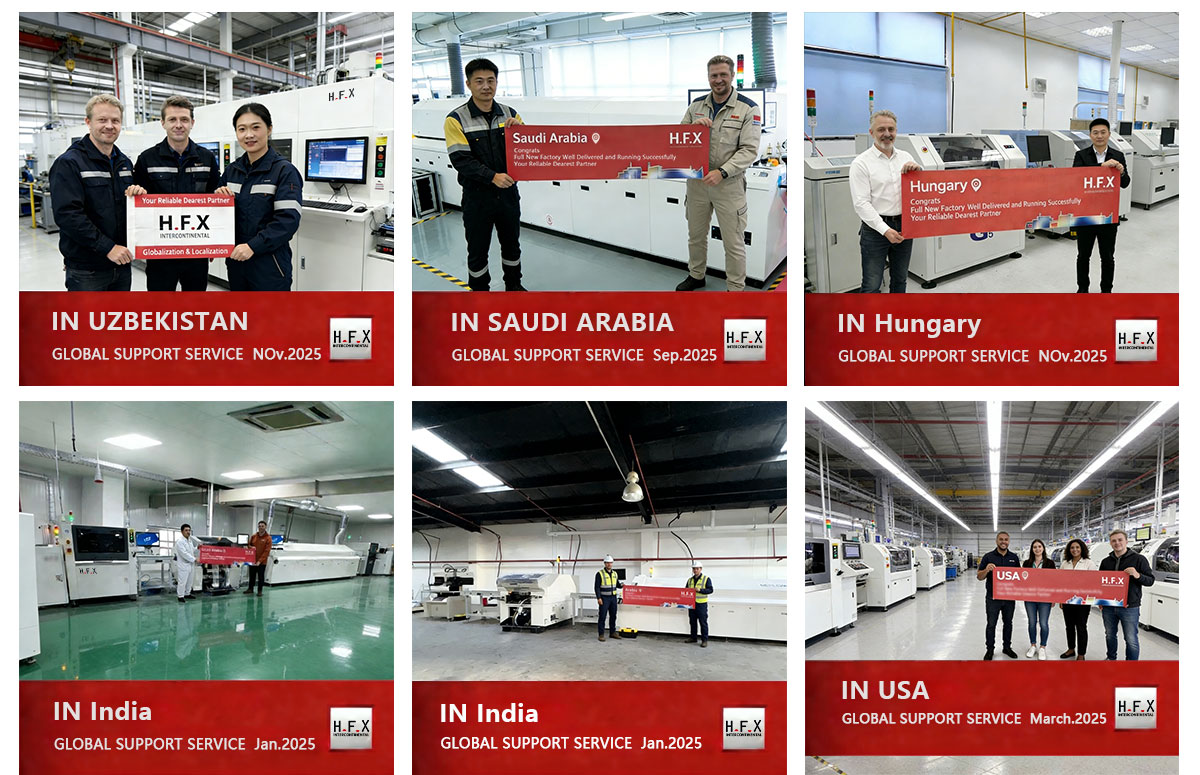

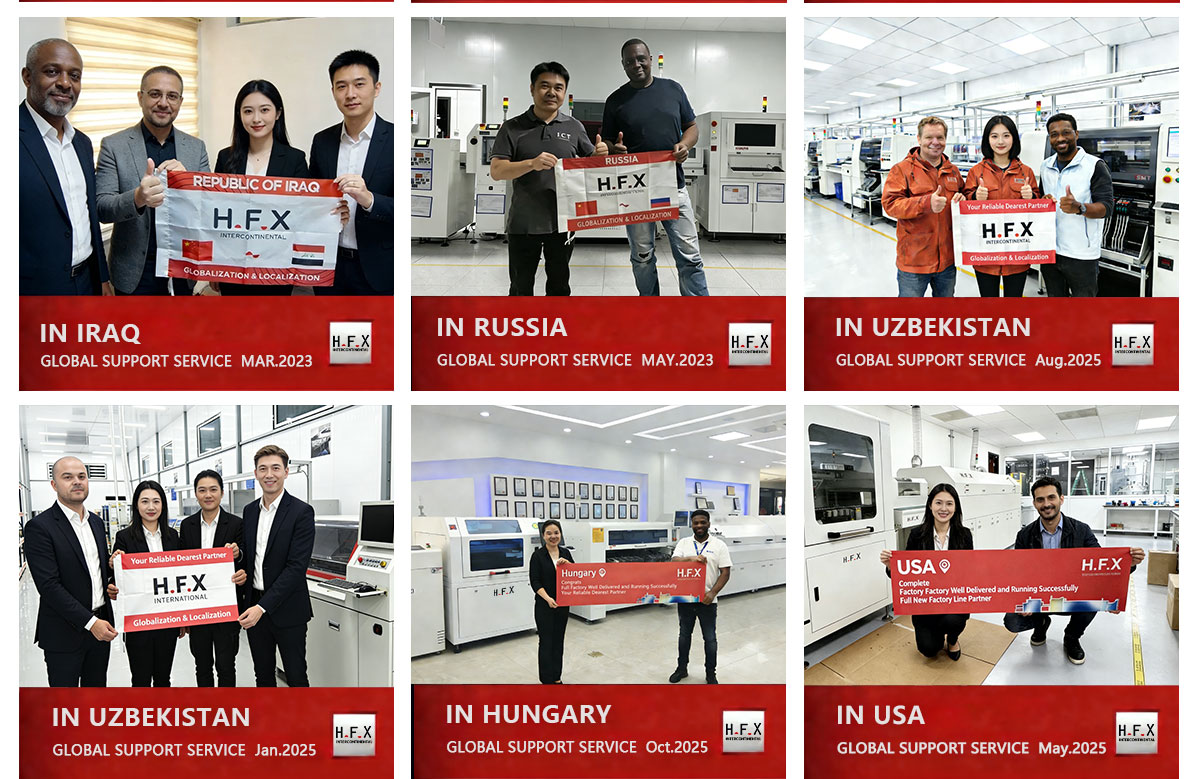

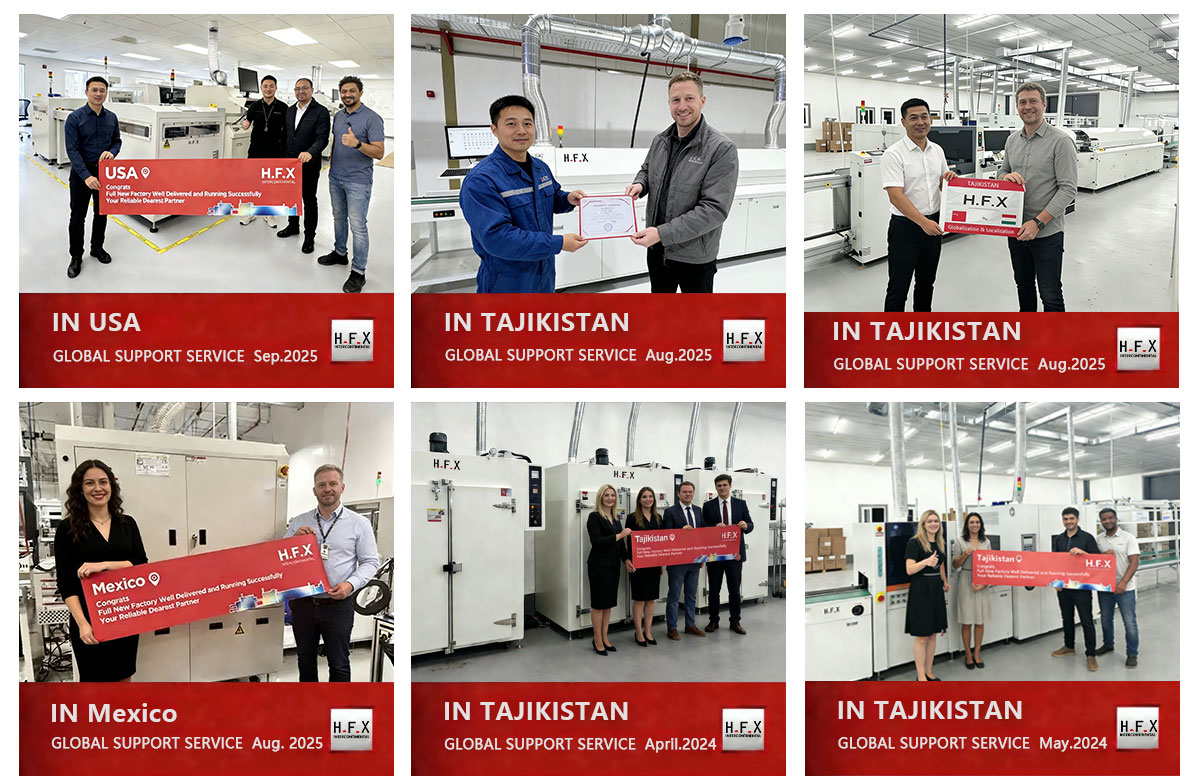

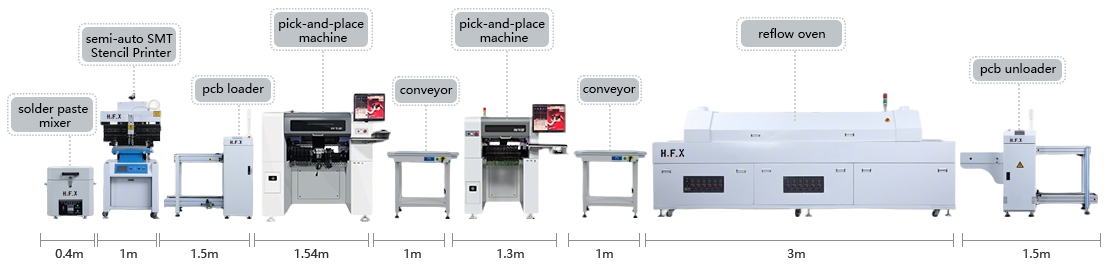

H.F.X is a supplier of fully automated SMT production line solutions, with its own manufacturing base. With 12 years of experience in SMT/DIP production line assembly, we utilize proven SMT production lines to achieve semi-automation or full automation. Equipment process: automatic loader, precision printer, high-speed picker, zoned reflow soldering, online AOI, xray inspection machine, intelligent unloader. One operator is responsible for the entire shift. Customers cover the global mobile phone, LED lighting, automotive, and television industries. 2 days for installation, including air, power, and exhaust preparation, 5-15 days for software training, maintenance, and safety training. We provide layout diagrams, bill of materials guidance, and return on investment predictions. Our 12 years of overseas service ensures a zero-risk start. We can configure suitable production line equipment according to customer production needs.

Features

1. Intelligent process

The fully automated SMT production line connects SMT production equipment through the MES system to achieve real-time control. The loader automatically detects the circuit board size. The printer uses vision to achieve micron-level high-precision alignment. The high-speed mounter can continuously supply from intelligent reels. The reflow soldering curve automatically adjusts the temperature according to the characteristics of solder paste and PCB. AOI can immediately mark defects through AI learning. The Xray detector can automatically identify and mark defective products. The unloader stacks or routes NG boards. Fully automated production achieves a 99.9% yield rate. It can process circuit boards ranging from 50 to 5000 millimeters at a time.

2. High-precision printing

The solder paste printer in the fully automatic SMT series applies solder paste through laser-cut apertures, with uniform scraping and pressing by left and right blades. The fully automatic solder paste printer features high precision, high speed, and stable operation. 3D SPI detects the height, volume, area, short circuit, and offset of solder paste. The steel mesh cleaning machine cleans the steel mesh every cycle. It supports lead-free or low-temperature solder paste.

3.Rapid multi-temperature zone reflow soldering

The ten-temperature zone reflow soldering maintains a temperature of ±0.3°C within the chain conveyor, achieving uniform heating through hot air convection or nitrogen protection. The nitrogen furnace reduces the risk of oxidation and enhances the brightness of solder joints. With segmented temperature control, each temperature zone can be independently adjusted to form a precise heating curve, reducing the failure rate of issues such as soldering defects and bridges. It is suitable for high-mix, fully automated SMT production lines.

4.AI-driven detection

After reflow, the AOI scans the circuit board through a high-speed vision system, captures images, and compares them with a standard parameter database. Through image processing, it identifies the location of defects and marks them for display. The software can be compared to golden samples. It detects defects such as bridging, displacement, and abnormal solder volume in soldering production. Specific algorithms are adopted for different detection items. It is essential for a fully automated SMT production line to have zero defects.

5. Modular expansion path

Starting from semi-automatic, we have upgraded to fully automatic through the introduction of plug-in SMT production equipment. The blueprint indicates reserved space for future SPI or buffer zones. The labor cost model predicts a 50% savings.

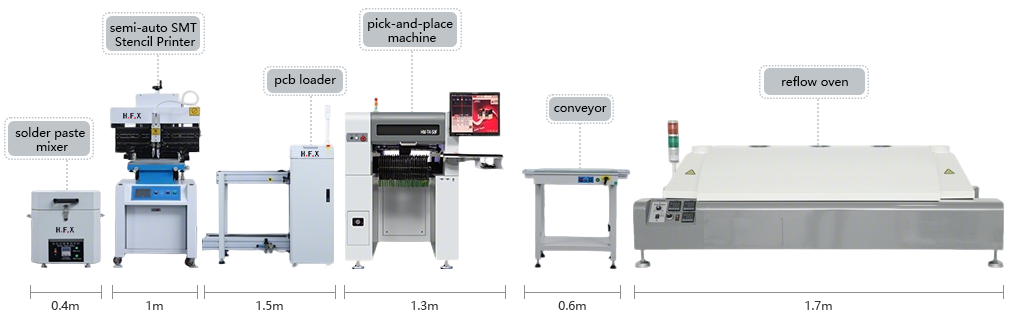

6. SMT line equipment list

The H.F.X high-quality PCBA production line is equipped with advanced equipment to achieve efficient and precise PCB assembly. The fully automated SMT series includes loaders, automatic printers for precise solder paste application, pickers for accurate component placement, reflow ovens for reliable soldering, and AOI systems for thorough defect detection. This high-quality PCBA production line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting the diverse needs of the industry.

| Product Name | Purpose in SMT Line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

Specification

| Category | Projects | Details |

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

Compliance Standards

CE marks electrical safety. RoHS verifies green materials. ISO9001 drives process control. Patents secure conveyor logic. Proof of dependable Fully Automated SMT Line.