PLW series tunnel style fully sealed nitrogen wave soldering product features:

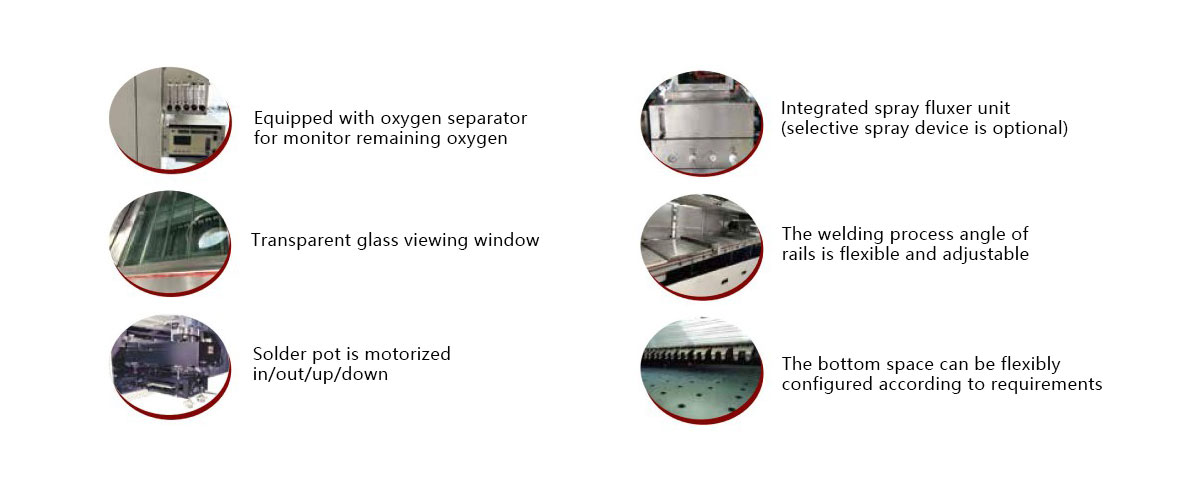

1. Transportation system: adopting a segmented floating structure to effectively prevent rail deformation; Innovative segmented transmission scheme

ensures smoother product delivery. The bottom space of the board can be flexibly configured;

2. Preheating system: adopting drawer type modular energy-saving design, infrared and hot air can be combined arbitrarily, temperature control adopts

PID method, infrared thermal compensation is configured in the preheating and tin furnace transition section to effectively reduce temperature drop;

3. Welding system: The tin furnace adopts external heating, and the inner liner of the tin furnace is made of cast iron, with anti-corrosion treatment on the

inner surface; The surroundings of the tin furnace are sealed with special elastic materials and equipped with an electric tin furnace, which can be freely

raised and lowered for entry and exit;

4. Nitrogen filling system: adopting the world's first welding area sealing solution, the welding angle is flexible and adjustable; Configure an oxygen

analyzer to monitor residual oxygen levels;

5. PC+PLC control system: Windows 10 operating system, Chinese/English operation interface, automatic storage function for process curves/data,

alarm for low or high flux level; Low tin level alarm.

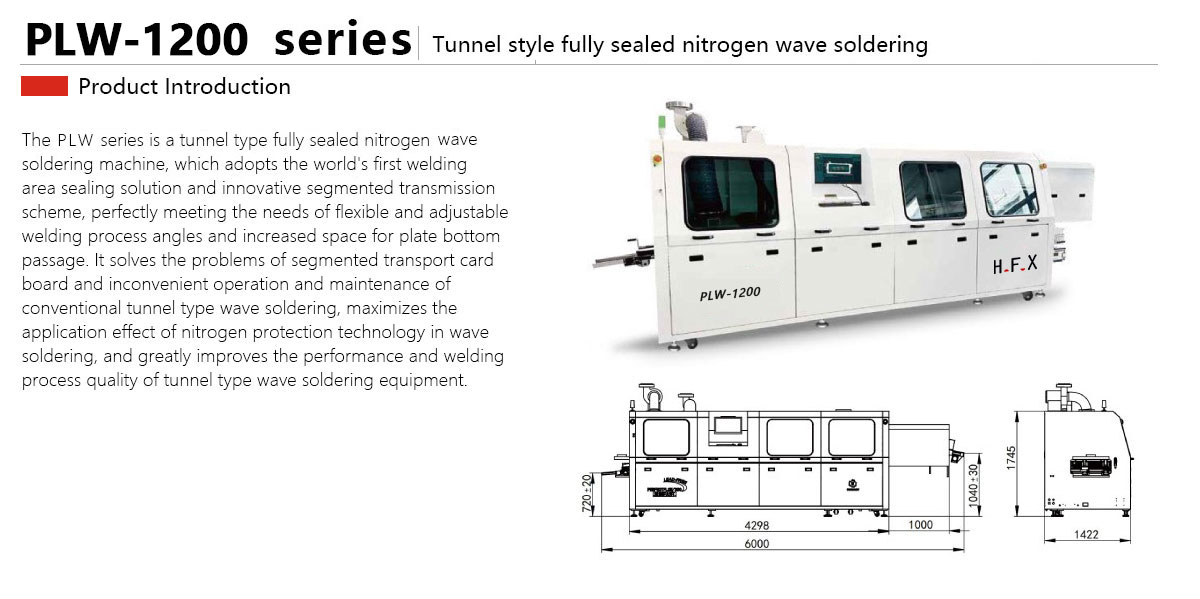

Product parameters:

| Model NO. | PLW/1200 | PLW/1250 | PLW/1280 |

| Dimension:L*W*H(mm) | 6000×1422×1750 | 6000×1522×1750 | 6000×1692×1750 |

| Weight | Appro×.1850kg | Appro×.2050kg | Appro×.2300kg |

| Power Supply | 3PH 380V 50HZ | 3PH 380V50HZ | 3PH 380V 50HZ |

| Start up Power | 33KW | 33KW | 45KW |

| Normal Running Power | Approx.8.5KW | Approx.9KW | Approx.11KW |

| Control System | PC+PLC | PC+PLC | PC+PLC |

| Spraying movement | Step motor | Step motor | Step motor |

| Spraying Pressure | 0.2Mpa~0.4Mpa | 0.2Mpa~0.4Mpa | 0.2Mpa~0.4Mpa |

| Flux Flow Control | Option | Option | Option |

| Auto Flux Filling | Standard | Standard | Standard |

| Exhausting | Top exhaust | Top exhaust | Top exhaust |

| Exhausting Pipe Diameter(mm) | φ250 | φ250 | φ250 |

| Exhaust fan power | 750 | 750 | 750 |

| Preheating Mode | Hot air convection/IR | Hot air convection/IR | Hot air convection/IR |

| Temperature Control Mode | PID | PID | PID |

| Preheating Zone Quantity | 3 | 3 | 3 |

| Preheating Zone Length(mm) | 1800 | 1800 | 1800 |

| Preheating Temperature Range | Room temperature~200℃ | Room temperature~200℃ | Room temperature~200℃ |

| Warm-up Time(min) | Approx.12min(setting:150℃) | Approx.12min(setting:150℃) | Approx.12min(setting:150℃) |

| Preheating Blower Motor | 250W 3PH 220VAC | 250W 3PH 220VAC | 250W 3PH 220VAC |

| Width(mm) | 50~350 | 50~450 | 50~610 |

| PCB Conveying Direction | L→R(Option:R→L) | L→R(Option:R→L) | L→R(Option:R→L) |

| Conveying Speed(mm/min) | 500~1800 | 500~1800 | 500~1800 |

| Conveying Height(mm) | 750±20 | 750±20 | 750±20 |

| Available Component Height(mm) | Upper(Top)120,Below(Bottom)15 | Upper(Top)120,Below(Bottom)15 | Upper(Top)120,Below(Bottom)15 |

| Conveying Speed Control Mode | Closed loop stepless speed regulation by inverter | Closed loop stepless speed regulation by inverter | Closed loop stepless speed regulation by inverter |

| Finger | Heavy type double hook finger | Heavy type double hook finger | Heavy type double hook finger |

| Option:Special jig for fixture | Option:Special jig for fixture | Option:Special jig for fixture | |

| Conveying Angle | 4.5~6.3° | 4.5~6.3° | 4.5~6.3° |

| Solder Pot Type | Mechanical | Mechanical | Mechanical |

| Solder Pot Material | Casting Iron | Casting Iron | Casting Iron |

| Wave Height Adjustment | Inverter:Digital Control by PC | ||

| Cooling type | Nitrogen knife cooling | ||

| Solder Pot Heating Power | 13.5KW | 13.5KW | 18KW |

| Max Solder Pot Temperature | 300℃ | 300℃ | 300℃ |

| Solder Pot Capacity | Approx.480kg | Approx.550kg | Approx.640kg |

| Wave Driving Power | 180W*2 3PH 220VAC | 180W*2 3PH 220VAC | 180W*2 3PH 220VAC |

| Solder Pot Warm-up Time | Approx.150min(setting:250℃) | Approx.150min(setting:250℃) | Approx.150min(setting:250℃) |

| Temperature Control Mode | PID | PID | PID |

| Finger Cleaning System | Brush | Brush | Brush |

| Nitrogen purity | 100.00% | 100.00% | 100.00% |

| Nitrogen consumption | Appro×.20m³/h | Appro×.22m³/h | Appro×.25m³/h |

| Nitrogen pressure | 0.4Mpa~0.6Mpa | 0.4Mpa~0.6Mpa | 0.4Mpa~0.6Mpa |

| External spraying unit (option) | PLW/1200-Z | PLW/1250-Z | PLW/1280-Z |

| 500mm The total length+500mm | |||

> Customization can be made according to customer needs.