Introduction to FL-340A milling cutter PCB splitter:

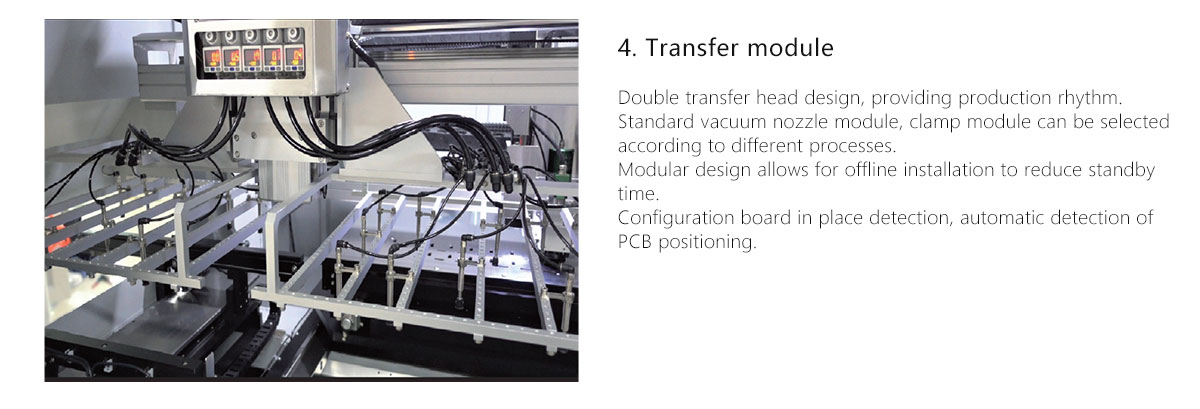

(1) The dual workbench can simultaneously perform cutting and circuit board placement, providing production capacity.

(2) Visual cameras are equipped with autofocus, eliminating the need for manual adjustment of focal length.

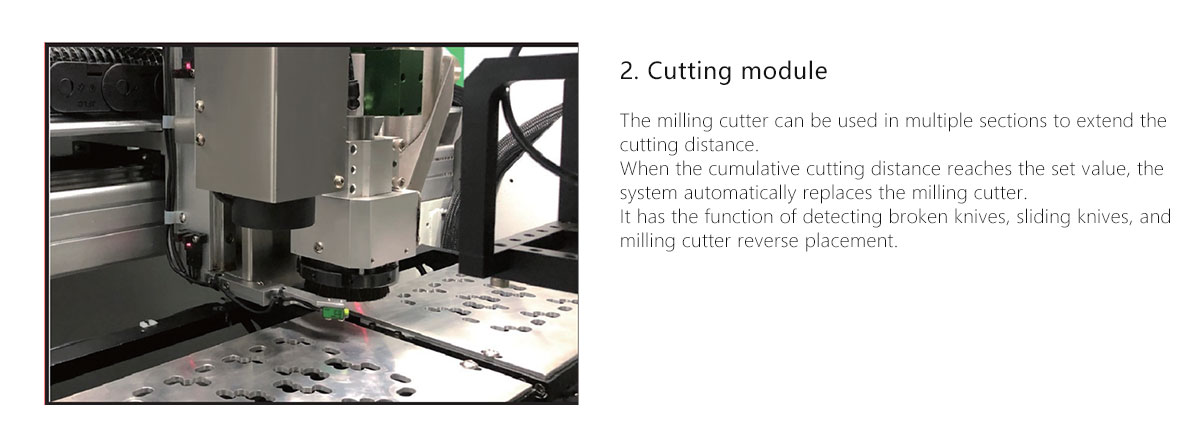

(3) Adopting high-speed spindle, with low cutting stress, high precision, and equipped with automatic tool changing module to achieve automated operation.

(4) Standard dust detection and alarm function of the dust collector to ensure effective vacuuming.

(5) Configure MES online function, provide management system integration of production data, and monitor equipment status.

Application of FL-340A milling cutter PCB splitter:

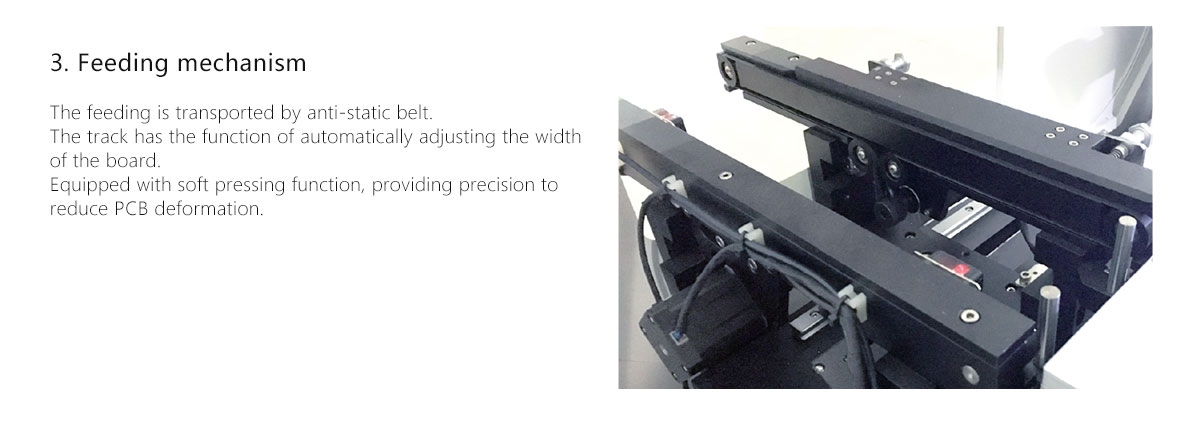

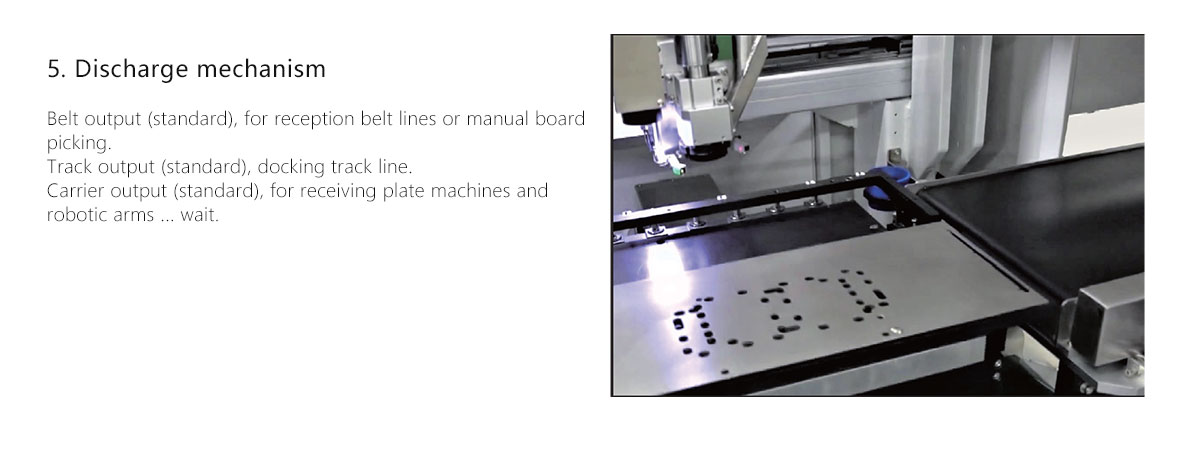

(1) Online operation, automatic feeding, cutting, waste board and finished board classification discharge have always saved labor.

(2) The entire series is equipped with a high-speed CCD visual alignment correction device, which is particularly suitable for high-precision and high-capacity PCB board splitting operations.

(3) Suitable for small multi connected PCB boards such as mobile phones, digital cameras, GPS, PDA, and MODULE.

(4) Expanding the size is suitable for processing large circuit boards such as digital TVs, PC hosts, workstations, servers, etc.

(5) Using dual work platforms to place workpieces reduces waiting time and increases production capacity.

(6) Various board collection schemes can be selected to achieve the goal of fully automated labor savings.

Product parameters:

| Item | FL-340A |

| Valid cutting size | 450*420mm |

| Cutting Function | Straight, L-shaped, U-shaped, Circular, Arc |

| Processing Table | Dual tables |

| Machine Repetition Accuracy | ±0.01mm |

| Cutting Accuracy | ≤±0.05mm |

| Loading Method | Track conveyor |

| Unloading Method | Belt conveyor or track conveyor(Option) |

| Spindle speed | MAX80,000RPM |

| Spindle Router bit Change Method | Automatic Tool Change |

| Program Teaching Method | CCD Image Intuitive Teaching Input |

| Router bit Detection Function | Equipped |

| Cutting speed | 1-100mm/s |

| Applicable Router bit size | ∅0.8-3.0mm |

| Air Source Requirement | 0.6MPa,155L/min |

| Standard dust collector | TS200L |

| Dimensions(W*D*H) | 2222*1567*1706mm |

| Power Requirement | AC110~220V, 50/60HZ, 4KW (Customization supported) |

| Weight | 1000KG |

> Equipment can be customized according to customer needs