Equipment features:

Three proof coating machine is a specialized equipment used for protective coating of electronic components, circuit boards, etc. It has the following main functions:

1. Precise spraying: Advanced spraying technology is adopted to achieve high-precision and uniform glue spraying, ensuring consistent coating effect.

2. Suitable for multiple types of adhesives: It can adapt to various types of adhesives, such as three proof paint, UV glue, AB glue, etc., to meet different coating needs.

3. Automated operation: Equipped with automated coating function, improving production efficiency and reducing manual operation errors.

4. Adjustable coating parameters: The spraying speed, adhesive strength, and other parameters can be adjusted according to different coating tasks and workpiece characteristics to achieve the best coating effect.

5. Efficient cleaning: Equipped with a cleaning device, it can quickly and effectively clean the spraying equipment, ensuring that the glue does not block the nozzle and ensuring the normal operation of the equipment.

6. Safety protection: Equipped with safety protection devices such as protective doors, emergency stop buttons, etc., to ensure the safety of operators.

7. Data recording and tracing: Automatically record relevant data of the coating process, such as coating time, coating number, etc.

8. Flexibility and Scalability: Customization design can be carried out according to production needs to adapt to workpieces of different sizes and shapes, while also having scalability for later upgrades and modifications.

9. Energy saving and environmental protection: Adopting energy-saving design to reduce energy consumption, while meeting environmental requirements and reducing the impact on the environment.

Product parameters:

| Category | Parameter name | Parameter values | Parameter | Value/Description |

Substrate specifications | Model | DH-450 | External dimensions | L915mmxW1200mm xH1630mm |

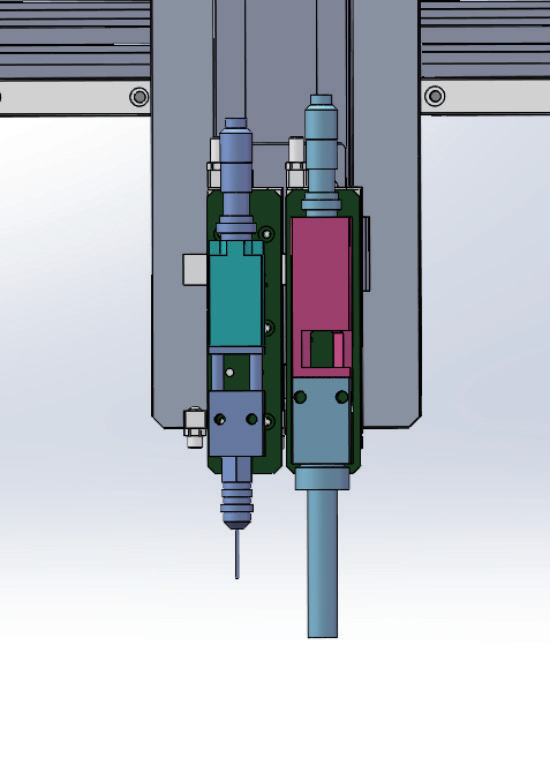

| Equipment weight | 350KG | Number of rubber valves | 1 small atomization+1 dispensing valve | |

| Glue bucket | 10 L | Cleaning bucket | 2L stainless steel bucket | |

| Track height | 900±20mm | |||

Motion axis parameters | Coating stroke | X=450 Y=450 Z=100(mm) | Width of conveyor guid erail | 50-450mm |

PCB component height | Up and down MAX100mm | PCB board edge | ≥5mm | |

| Spray adhesive width | 3-20mm | Coating edge accuracy | <1mm | |

| Coating thickness | 0-300um adjustable | Upper layer transmission accuracy | 920±20mm | |

| Transport Direction | L-R R-L | Transportation speed | 2-12m/min | |

| Transport motor | Stepping motor | Three axis drive speed | 800mm/s | |

Three axis drive accuracy | ±0.02mm | |||

Electrical parameters | Power supply | AC110~220V 50/60Hz | Total power | 1.8KW |

| Gas source | 0.4-0.6Mpa | Exhaust air volum erequirements | 6m³/min | |

Software parameters | Programming method | Manual indication | Software section | Win10+coating software |

| Control mode | Industrial computer+ motion control card | Communication Port | SMEMA interface | |

Number of program storage | More than 1000 | Total power | 1.8KW | |

Valve body parameters | Spraying method | Atomization/dispensing | ||

Spray precision parameters | Coating edge accuracy | <1mm | Coating thickness | 0-300um adjustable |

> Customization can be made according to customer needs.