Equipment Function Description:

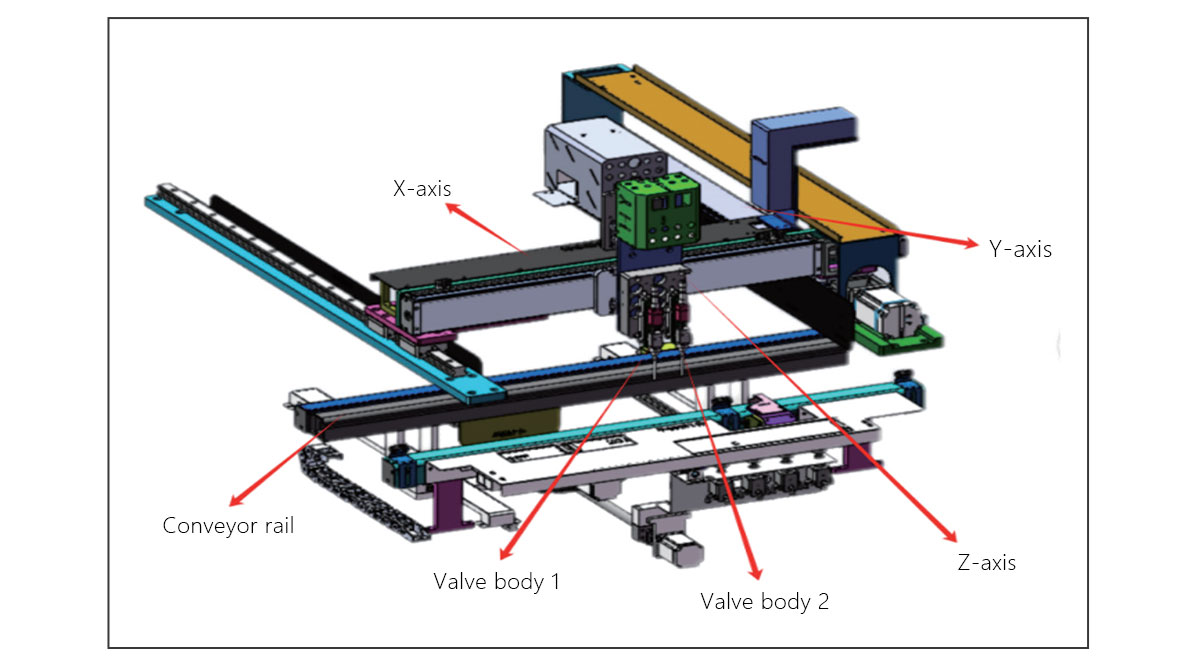

1.X、Y、Z 、 Three axis motion, accurately achieving selective spraying technology for various circuit boards to avoid non coated areas such as connectors.

2. Independently mold aluminum alloy guide rails and stainless steel chains for quick and convenient maintenance.

3. Full sheet metal rack platform ensures stable and accurate three-axis operation.

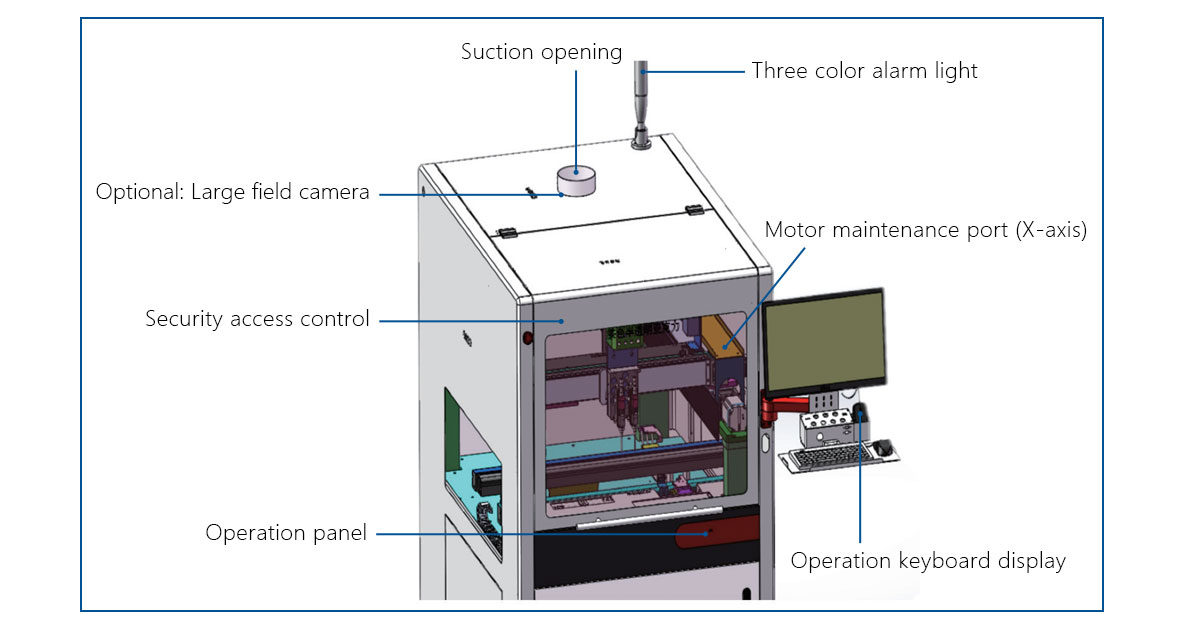

4. The software and electrical system are equipped with safety protection, and sound and light alarms for abnormal situations.

5. The device is equipped with intelligent automatic width adjustment function.

6. Programming method: keyboard+mouse teaching programming mode.

7. The device is equipped with a rubber valve that automatically soaks during standby and a rubber hose that automatically cleans.

Equipment features:

1. Servo motor and screw module drive control method, high rigidity, smooth operation;

2. The stainless steel gun valve has a uniform spraying effect and stable spraying quality. Easy to clean, no glue leakage, no air leakage;

3. High speed and precision, significantly improving work efficiency;

4. Easy installation; Humanized computer editing program settings, easy to operate;

5. The coating machine has teaching functions such as drawing points, lines, arcs, circles, and inputting programs for continuous irregular curve filling;

6. Continuous coating function for irregular curves such as points, lines, surfaces, and arcs;

7. Applicable adhesives: silicone, UV glue, polyurethane, acrylic, epoxy resin glue, sealant, hot glue, lubricating grease, silver glue, red glue, transparent paint, screw fixing agent, etc;

8. Scope of application (different types of configured valves):

(1) Semiconductor packaging; (2) PCB electronic component fixation and protection; (3) Quantitative liquid filling coating; (4) Coating of hardware components; (5) Glue dispensing in various industries.

Product parameters:

| Type | Specifications | Model parameter | Specifications | Model parameter |

Factory requirements | Model | DH-550 | External dimensions | L1059mmxW1410mm xH1650mm |

| Power supply | AC110~220V 50/60HZ | Total power | 1.8KW | |

| Equipment weight | 630KG | Gas source | 0.4-0.6MPa | |

Exhaust air volume requirements | 6m³/min | |||

| Coating parameters | Coating stroke | X=500 Y=500 Z=150(mm) | Conveyor rail width | 50-500mm |

| PCB component height | Up and down MAX120mm | PCB board edge | ≥5mm | |

| Spray adhesive width | 3-20mm | Coating edge accuracy | <1mm | |

| Coating thickness | 0-300um adjustable (depending on the actual situation of the adhesive) | |||

Control and Operating System | Programming method | Manual indication | Software section | W10+Coating Software |

| Control mode | Industrial computer+motion control card | Communication Port | SMEMA interface | |

| Delivery system | Rail amplitude modulation method | Software electric control | Upper layer transmission height | 920±20mm |

| Transport Direction | L-R R-L | Transportation speed | 2-12m/min | |

| Transport motor | Stepper Motor Control | Three axis drive mode | Servo motor+ball screw | |

| Movement system | Three axis drive speed | 800mm/s | Three axis drive accuracy | ±0.02mm |

| Conveyor guide rail | Specialized aluminum alloy+stainless steel chain | Program storage quantity | More than 1000 | |

| Testing section | Testing section | Comes with a built-in detection light source | Spraying method | Atomization and dispensing |

| Lighting section | Comes with built-in lighting source |

> Customization can be made according to customer needs.