Product Introduction:

(1) Pneumatic output, solenoid valve control, fast speed.

(2) The cutting process is vibration free and noise free, preventing damage to precision parts.

(3) The machine has a solid structure and is easy to operate, even unskilled personnel can operate it.

(4) PCB boards or sheets without V-groove design can be customized with trays and anti misoperation positioning devices.

(5) The height of the upper and lower knives can be adjusted, and the upper twist adjusts the tool gap according to the thickness of the PCB board to conform to the thickness between the V-grooves.

(6) Pneumatic lightweight design, built-in positioning sensor, can complete the cutting process without shear stress in one go, especially suitable for cutting aluminum substrates.

(7) The fit and wear can be adjusted by twisting the lower blade into front and rear sections without the need for shims, reducing the difficulty of tool replacement and adjustment. The blade can be repeatedly ground, saving high blade repurchase costs.

(8) The bow shaped waves and micro cracks generated when dividing the board without a circular blade make the wedge-shaped tool linearly separate the board, reducing the shear stress to the minimum, and ensuring that sensitive SMD components and even capacitors are not affected, minimizing the potential quality risk of the product.

(9) The cutting stroke is below 1mm, with no operational safety concerns. The cutting tool is made of high-speed steel precision grinding, which can be repeatedly ground and used. It is also suitable for thin plate splitting operations without V-CUT.

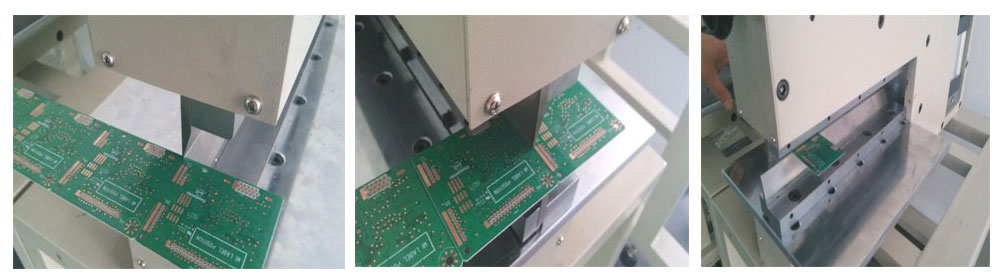

Application case:

Product parameters:

| Project | FM-30P |

| Device Name | German cutting PCB board splitter |

| Thickness of the split board | 0.3-3.5m |

| Working air pressure | 0.5-0.7MPA |

| Voltage | AC110-220V (Customization supported) |

| PCB cutting thickness range | 0.1mm~2.0mm(With V groove) |

| 0.1mm~1.0mm(No V groove) | |

| Equipment use range | All SMD PCB boards with V-CUT can be used with this machine |

| Effective cutting length | 330mm、430mm、530mm |

| Device size | 750*450*1200mm、980*500*1250mm、1200*810*1300mm |

| Mechanical weight | 160KG、300KG、450KG |

> Equipment can be customized according to customer needs