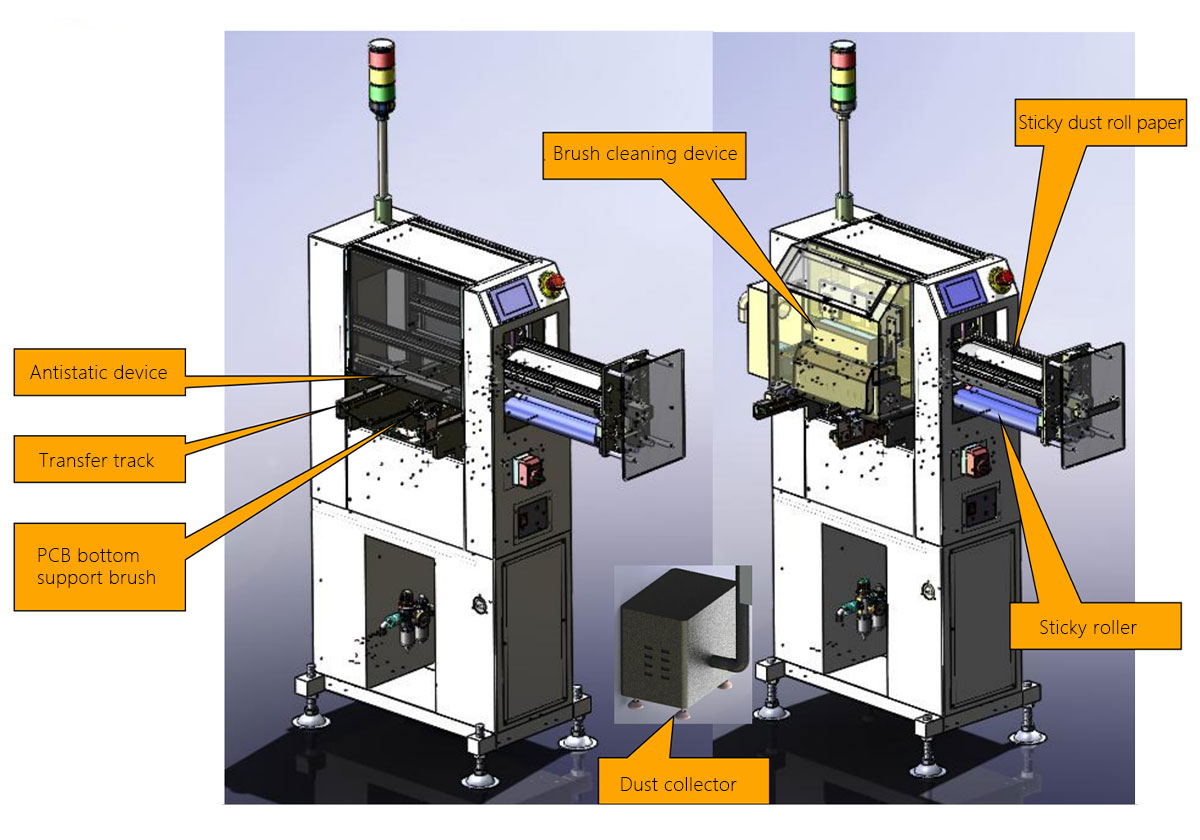

Equipment Overview:

The fully automatic PCB surface cleaning machine is suitable for online cleaning of small board debris, dust, fibers, hair, skin debris, metal particles and other foreign objects on the surface of PCB pads before solder paste printing or adhesive coating, ensuring that the PCB surface is in a clean state, eliminating welding defects such as virtual soldering, empty soldering, warping, and deviation in advance, thereby reducing hidden dangers and improving product quality. A specialized equipment developed and designed according to the PCB cleaning requirements of the FRT production line. Standard equipped with anti-static function, completely eliminating static interference. The contact cleaning method achieves a cleaning rate of over 99%, ensuring efficient, stable, and long-lasting cleaning effects.

Product Structure and Function:

The equipment mainly consists of a rack, brush mechanism, dust roller mechanism, vacuum cleaner, anti-static device, PCB board conveyor mechanism, human-machine control display screen, and electric control box.

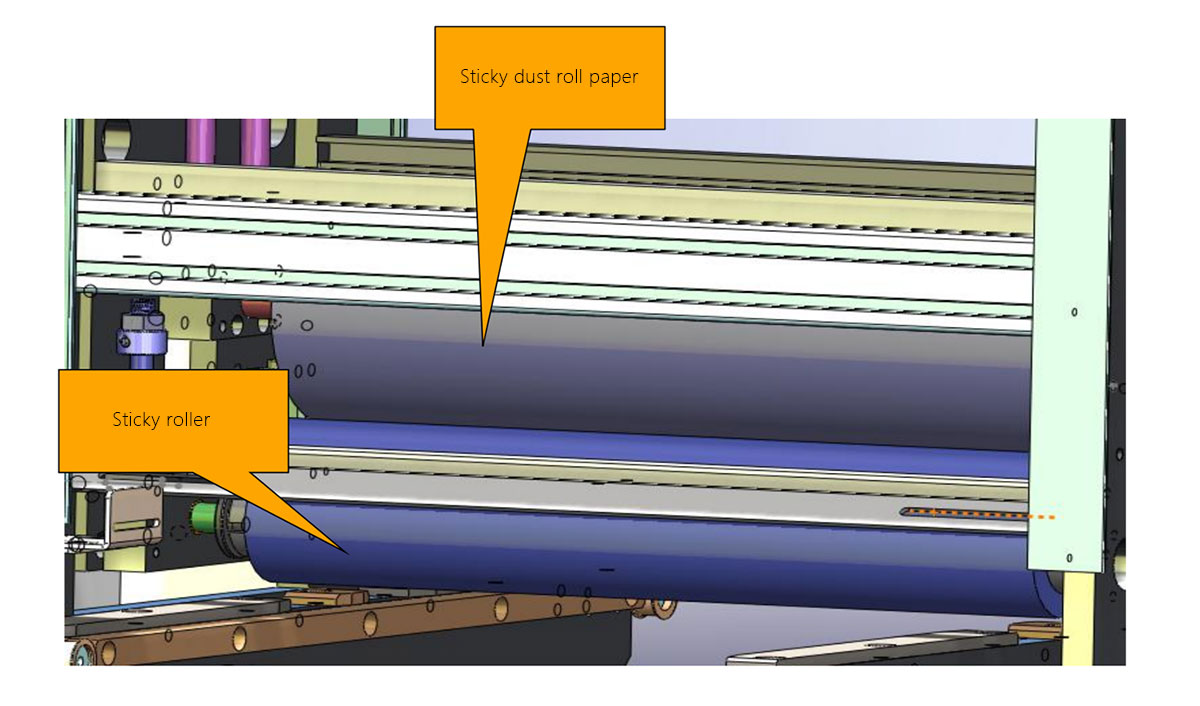

Roller cleaning device

Main structural components:

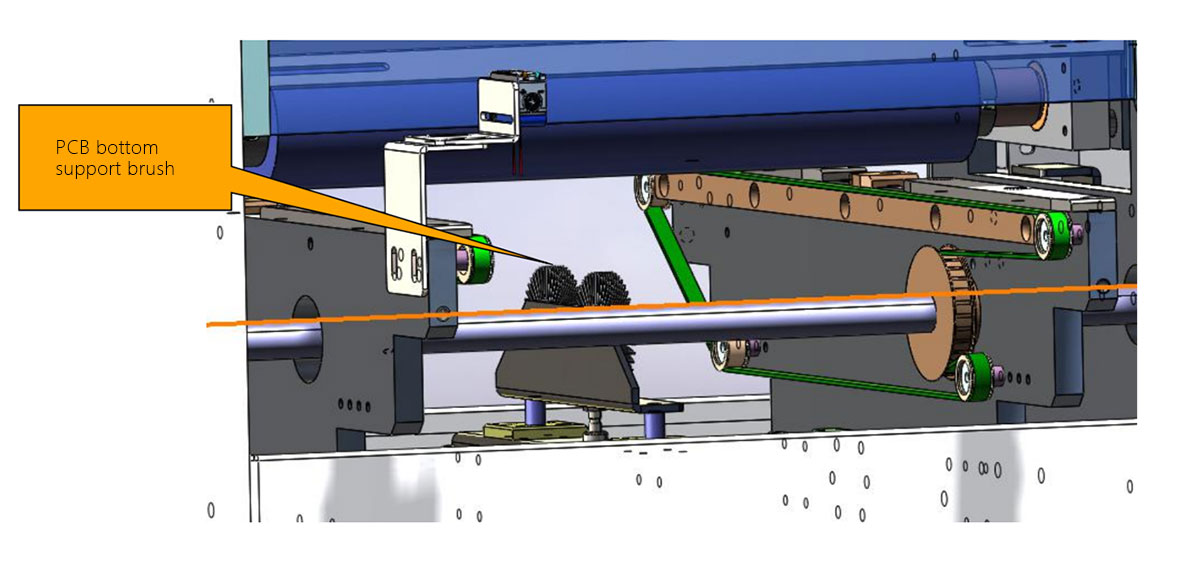

Bottom support device:

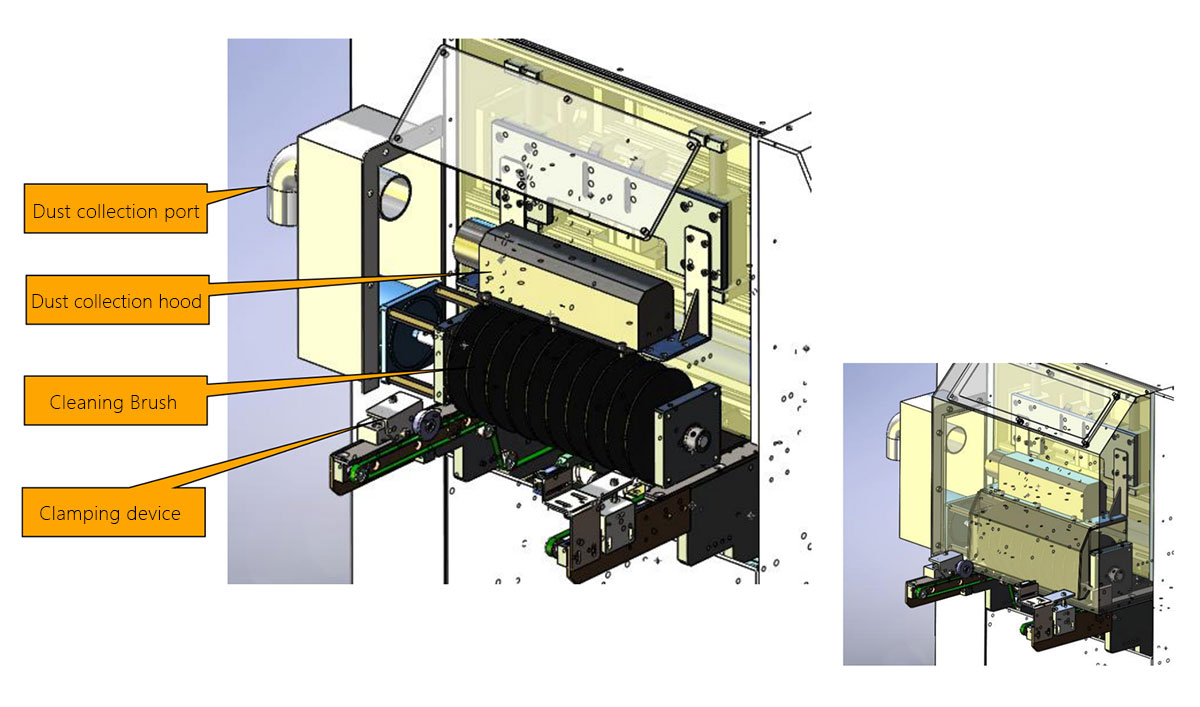

Brush cleaning device:

Product features:

1.Adopting a touch screen control interface, the operation is simple and easy to understand.

2. The feeding direction of the track can be switched freely, from left to right or from right to left.

3.The front end has a brush function, which has a stronger ability to remove debris, hair, and other debris.

4.Both the entrance and exit of the PCB board are equipped with anti-static devices to reduce the occurrence of chip defects and damage caused by static electricity during the chip placement process.

5.Equipped with counting function and CNC speed display function.

6.Reminder function for replacement cycle of sticky dust roll paper.

7.Developed and designed anti-static cleaning brushes and vacuum cleaners based on the high cleaning requirements of PCB boards, ensuring efficient and stable cleaning results.

Product parameters:

| Project | Specifications/Parameters | Notes |

| PCB Size | 50x500 (LxW)mm | Corresponding to other models of large substrates |

| PCB Thickness | 0.5~3.2mm | Special correspondence for substrates below 0.4mm |

| Transfer height | 900±25 mm | |

| Cleaning Brush | 1pcs | |

| Vacuum cleaning device | 1pcs | |

| Sticky dust roller | Front and back two | |

| Sticky paper | 1 roll | |

| Track direction | Left → Right or Right → Left | Optional |

| Fixed edge of track | Front fixed or rear fixed | Optional |

| Track width adjustment | Hand movement | Automatic track width adjustment optional |

| Antistatic device | Built-in | Special anti-static device selection |

| Gas source | 0.4-0.5MPa | |

| Power supply | AC220V,50HZ | Special voltage needs to be specified |

| Dimensions (mm) | 950X650X1400 | |

| Weight | 140KG |

> Customization can be made according to customer needs.