Characteristics of semiconductor specific reflow soldering products:

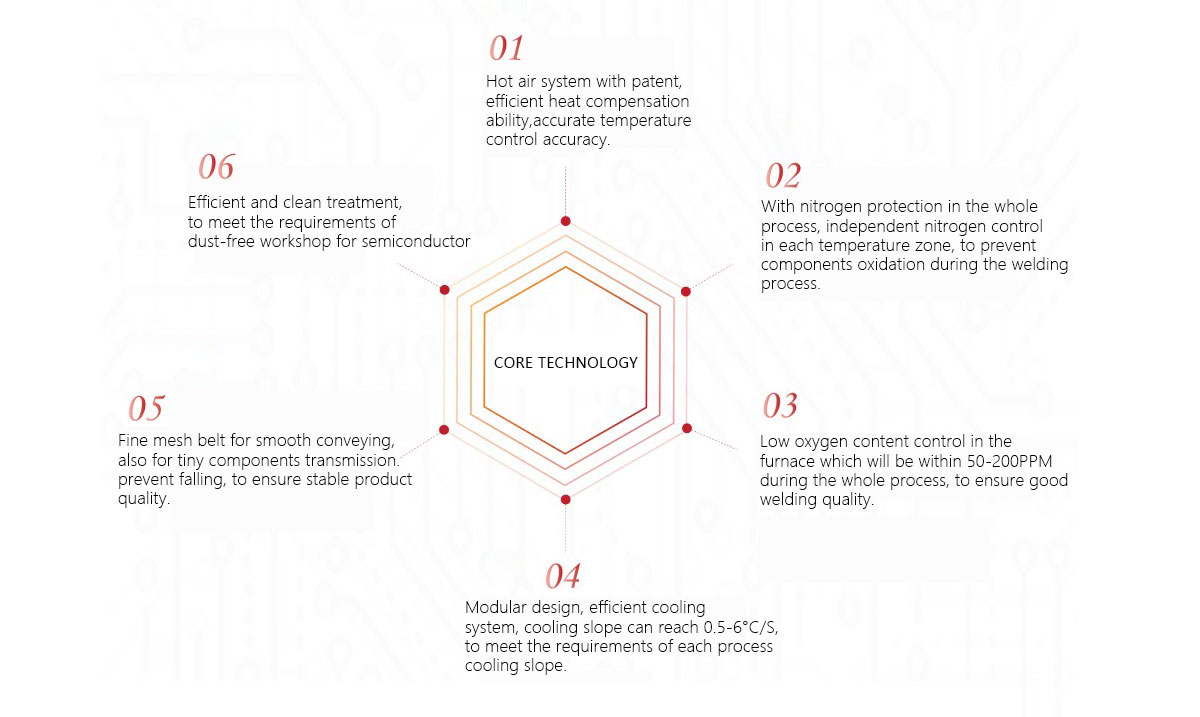

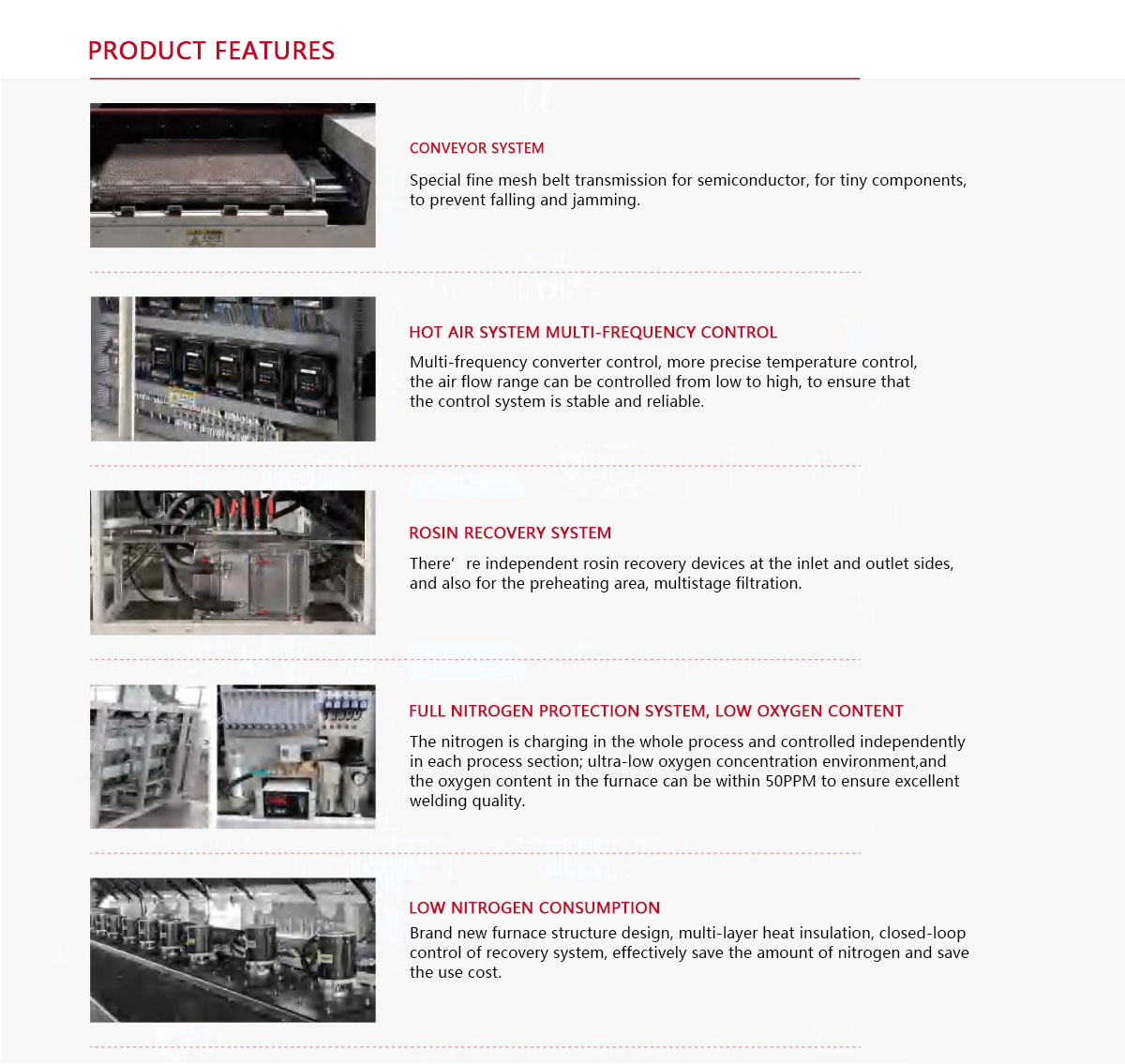

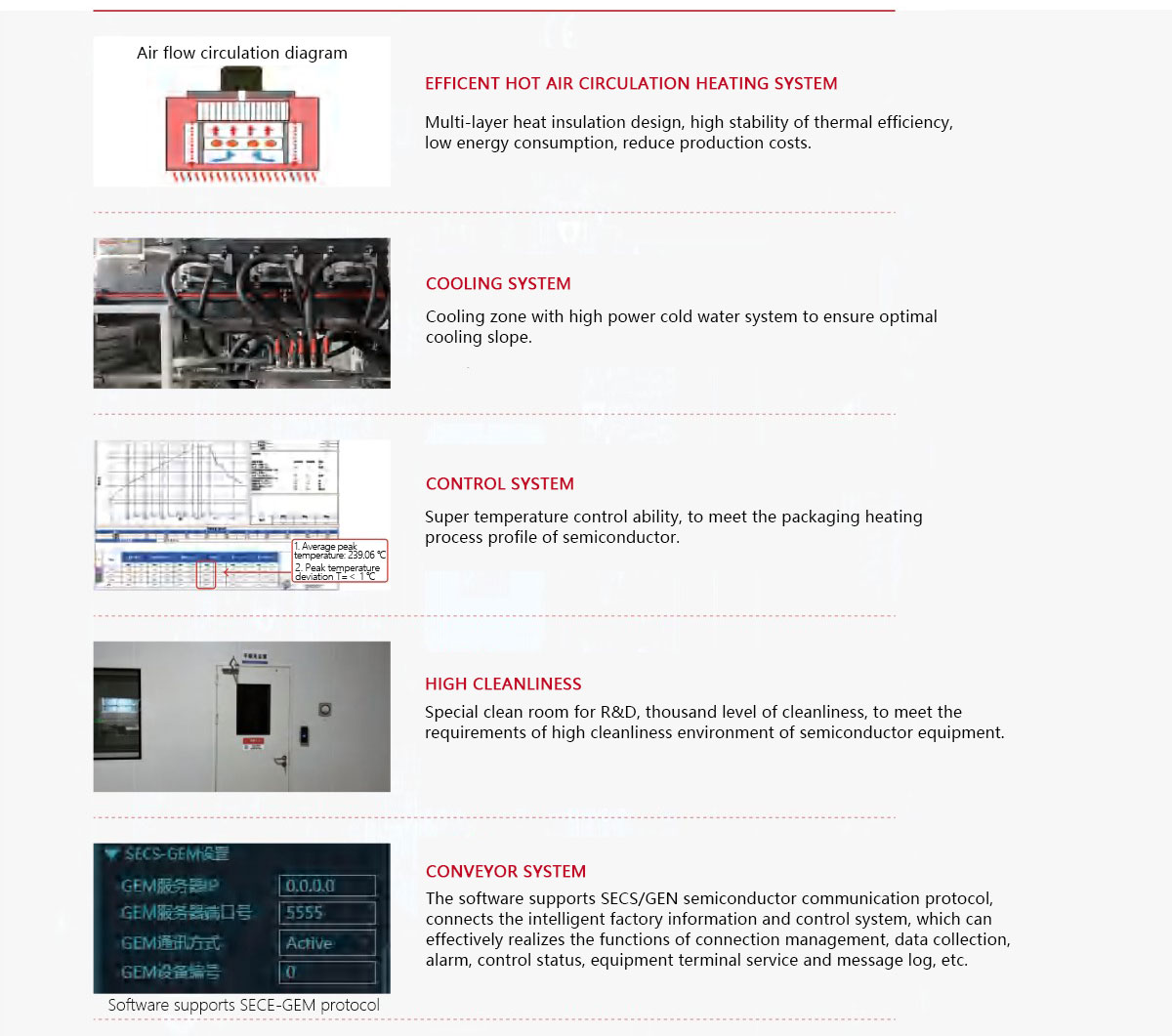

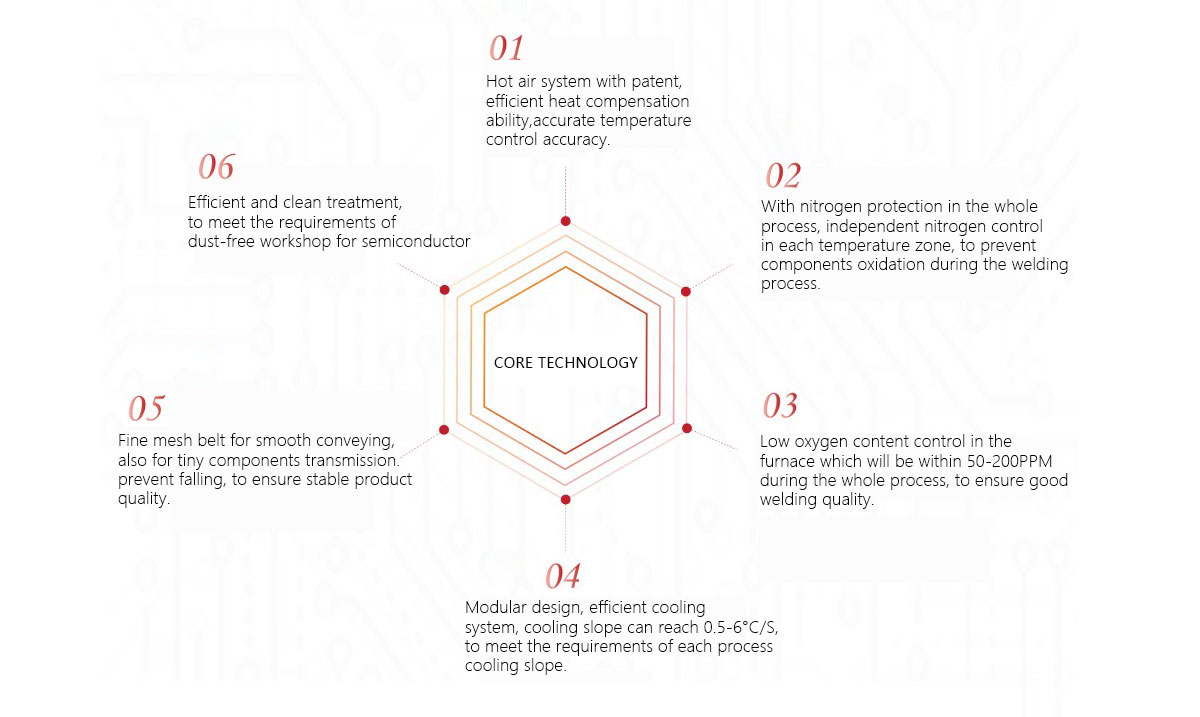

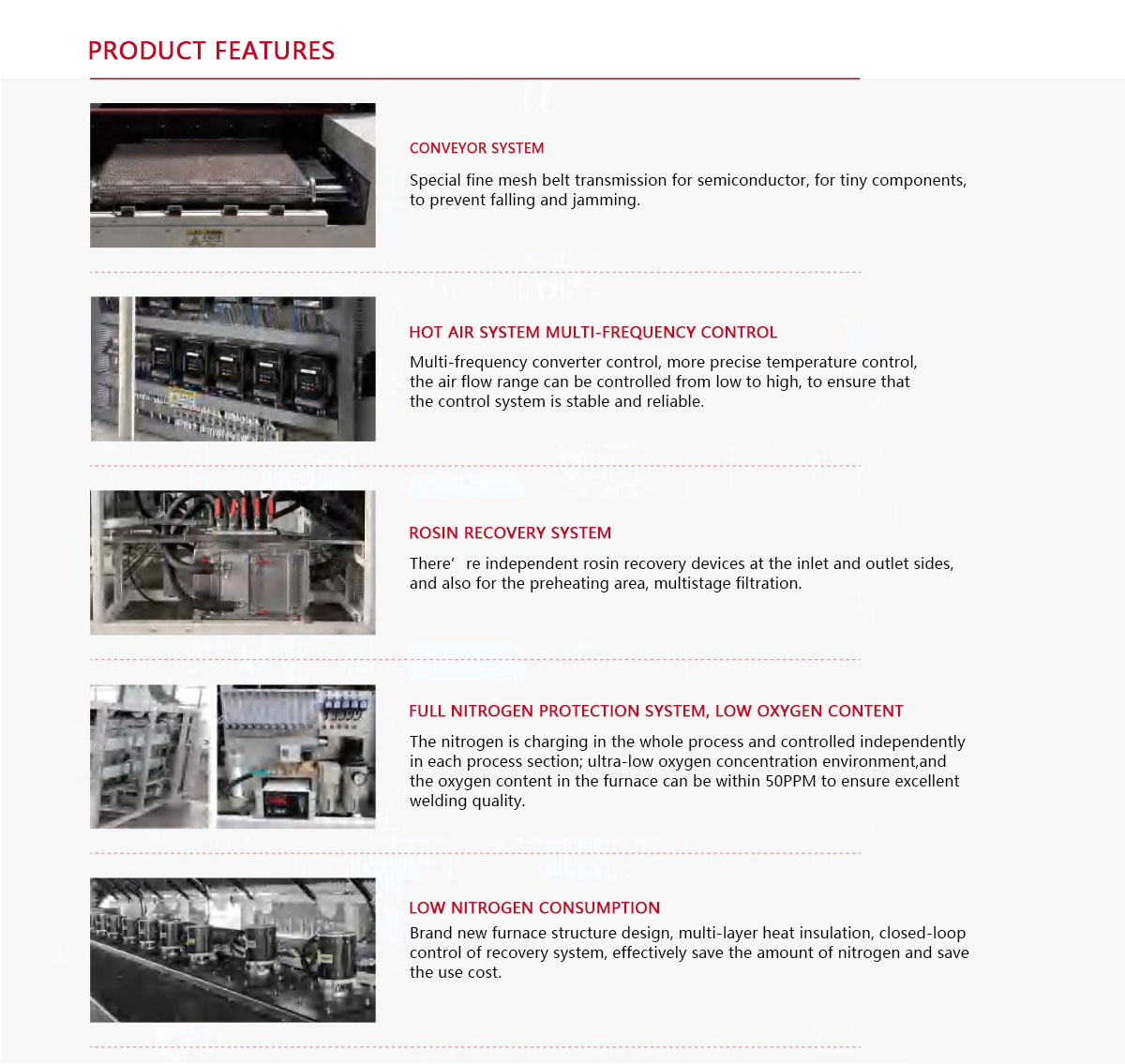

1. Patent hot air system, efficient thermal compensation capability, precise temperature control accuracy;

2. Full process nitrogen protection, independent control of nitrogen in each temperature zone to prevent oxidation of components during welding;

3. Low oxygen content control in the furnace, real-time display, the oxygen concentration throughout the process can be controlled within 50-200PPM, ensuring excellent welding quality;

4. Modular design, efficient cooling system, cooling slope can reach 0.5-6 ℃/S, meeting the cooling slope requirements of various processes;

5. The fine mesh belt can smoothly transport small components to prevent dropping and ensure stable product quality;

6. Efficient and clean processing to meet the requirements of semiconductor dust-free workshops.

Product parameters:

| Model No | HRM-6000 | HRM-6100 | HRM-6200 |

| Heating system |

| Heating zone structure | 8 heating zones, 16 heating modules | 10 heating zones, 20 heating modules | 13 heating zones, 26 heating modules |

| Heating zone length | 2950mm | 3670mm | 4750mm |

| Heating up time | 20min | 25min | 25min |

| Outlet Exhaust Diameter,valume | 2-Φ145,Exhaust demand 10m³/min x2 |

| Cooling system |

| Cooling type | Three cooling zones:forced water cooling |

| Cooling zone length | 1250mm |

| Chiller power | 5P Water chiller (Optional: connected to customer workshop cooling water) |

| Conveyor system |

| Conveyor Type | Fine mesh mesh belt (Optional: B-shaped mesh belt, force bone mesh belt) |

| Conveyer Direction | L→R,R→L |

| Converyer Height | 900±20mm |

| Mesh belt width | 24"(Other width sizes can be customized.) |

| Cmponent Height | 20mm |

| Conveyor Speed | 300mm-2000mm/min |

| Control system |

| Power | AC3Ø 5W 380V 50/60HZ |

| Total Power | 70KW | 89KW | 118KW |

| Startup Power | 35KW | 38KW | 42KW |

| Normal consumption | 10KW | 12KW | 14KW |

| Temp Control Range | Room temperature to 320℃ |

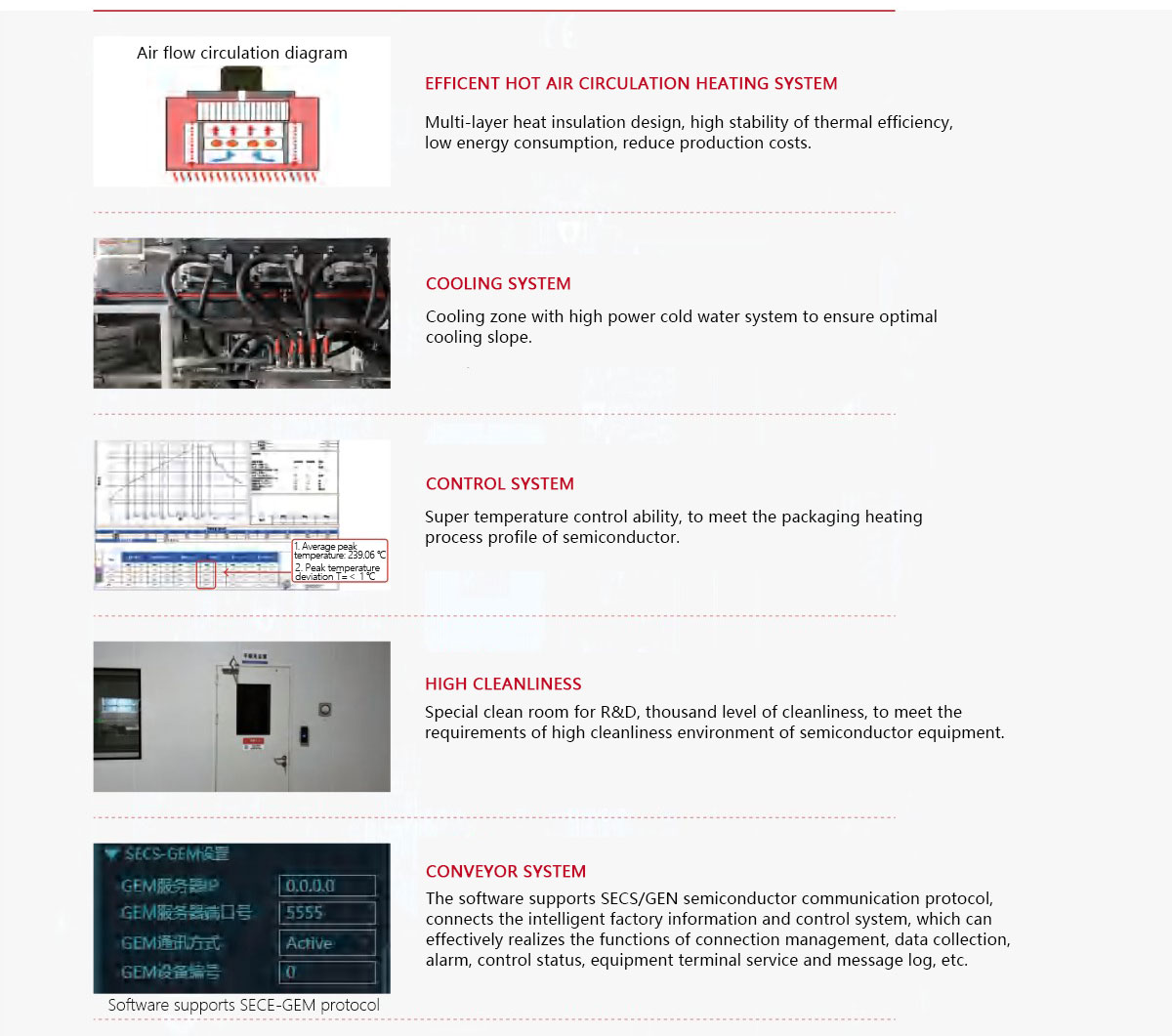

| Control type | PC+PLC Control system |

| Temp Control accuracy | ±1℃ |

| PCB Temp Deviation | ±1.5℃ |

| Data Storage | Process Data and status stotage |

| Power Outage Protection | Equipped with UPS |

| Operation Interface | Windows Chinese simplified, English online free switching |

| N2 area | Full nitrogen filling |

| Secs/Gemcommunication protocol | Standard |

| MES communication protocol | Standard |

| Computer | Commercial computer |

| General |

| Dimension(LxWxH) | 5680x1710x1650mm | 6400*1710*1650mm | 7500*1710*1650mm |

| Weight | 2400-2600kg | 3200-3400kg | 3600-3800kg |

| Flux recovery system | Standard |

| Color | Bright wrinkled white |

> Customization can be made according to customer needs.

FAQ:

Q: What is a reflow oven?

A: A reflow oven is a vital machine in electronics manufacturing. It is designed to heat and melt solder paste, allowing it to create secure connections between electronic components and printed circuit boards (PCBs) during the surface mount technology (SMT) assembly process.

Q: Why use a reflow oven?

A: Reflow ovens offer precise and consistent soldering, making them indispensable in electronics manufacturing. They ensure high-quality solder joints, compatibility with miniature components, and are essential for modern PCB assembly.

Q: What are the stages of reflow oven?

A: The reflow oven process typically consists of preheating, solder paste reflow, and cooling stages. Preheating gradually raises the temperature to activate the flux and remove moisture. The solder paste then reflows to create connections, followed by cooling to solidify the solder joints.

Q: What is the difference between reflow oven and wave soldering?

A: Reflow ovens are used for SMT assembly, heating solder paste to create precise connections. In contrast, wave soldering is employed for through-hole components, using a wave of molten solder to solder the bottom side of PCBs. Each method serves different assembly needs in electronics manufacturing.

H.F.X - Our Company

About H.F.X:

H.F.X is a leading provider of factory planning solutions and industrial inspection solutions. We have 4 wholly-owned factories that provide professional consulting and services to global customers. We have over 12 years of experience in electronic integrated solutions and industrial testing solutions. We not only provide a complete set of equipment, but also offer comprehensive technical support and services, and provide customers with more reasonable professional advice. We help many clients establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We will establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We have also obtained strict industry certifications such as CE, FDA, AERB, etc. Our products are exported to countries such as the United States, Germany, India, Singapore, Vietnam, Thailand, Canada, the United Kingdom, France, Italy, the Netherlands, Sweden, Mexico, Brazil, etc. We are trustworthy.

Exhibition:

For SMT factory setup and industrial non-destructive testing, we can provide you with:

1. We provide you with complete SMT solutions and industrial testing solutions

2. We Provide Core Technology With Our Equipments

3. We provide the most professional technical services

4. We have rich experience in establishing SMT factories and industrial testing

5. We can solve any problems related to SMT and industrial testing

Semiconductor-specific reflow soldering