Product features:

1. Alignment accuracy: ± 10.0 micron/micron @ 6 σ, Cp ≥ 2.0.

2. Printing accuracy: ± 20.0 micron/micron @ 6 σ, Cp ≥ 2.0.

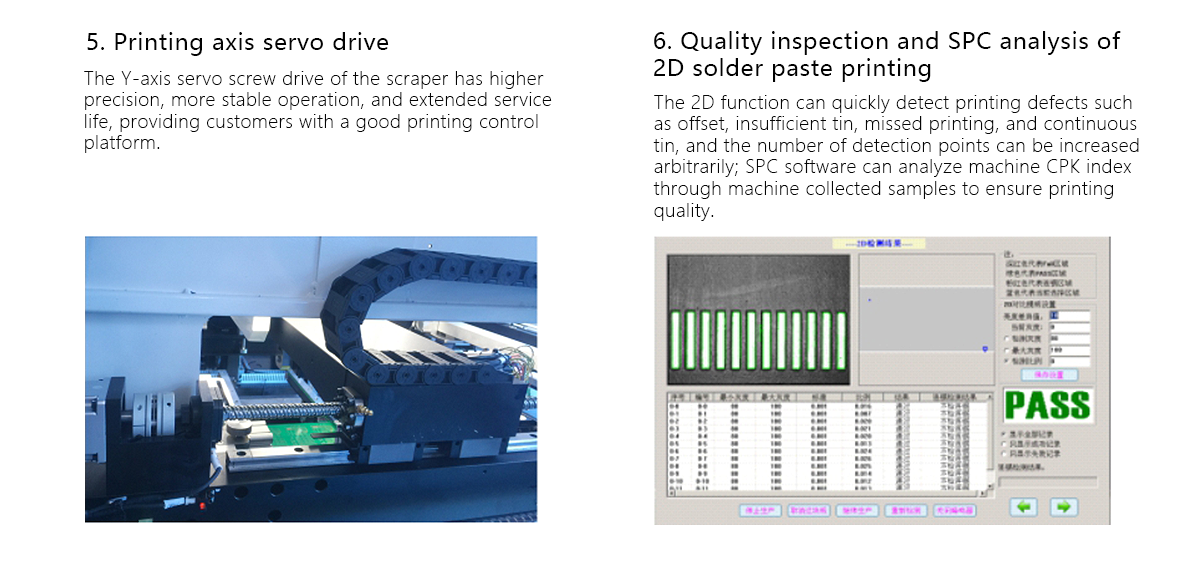

3. With a simple and reliable structure, precise positioning, and easy adjustment, it can quickly achieve automatic adjustment of the lifting height of PIN pins on PCB boards of different thicknesses; The atomizing nozzle evenly sprays the cleaning solution onto the wiping paper, and the arc-shaped rubber wiping plate is soft, wear-resistant, and corrosion-resistant, with strong bi-directional vacuum cleaning thoroughly. The length of the wiping paper tube can be adjusted from 250mm to 450mm, and can achieve functions such as dry cleaning, wet wiping, wet washing, and reciprocating cleaning.

Product parameters:

| PCB Parameters | |

| Maximum board size (XxY) | 450mm x350mm |

| Minimum board size (XxY) | 50mmx50mm |

| PCB Thickness | 0.4mm~6mm |

| Warpage | MAX. PCB Diagonal 1% |

| Maximum board weight | 3Kg |

| Gap at the edge of the board | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transmission speed | 1500mm/Second(Max) |

| Direction of transmission track | 900±40mm |

| Transmission mode | Left-Right, Right-Left, Left-Left, Right-Right(Program Settings) |

| PCB clamping method | One segment track |

| Plate support method | Programmable elastic lateral pressure+adaptive plate thickness+edge locking substrate clamping (options: 1. Bottom multi-point local vacuum: 2. Bottom integral suction chamber vacuum) |

| Printing Parameters | |

| Print Head | Suspended intelligent printing head (two independent direct coupled motors) |

| Module frame size | 470mm*370mm-737mm*737mm |

| Maximum printing area (XxY) | 450mm x350mm |

| Scraper method | Steel scraper/adhesive scraper (angle 45 °/55 °/60 ° selected according to printing process matching) |

| Squeegee length | 300mm (optional 200mm-500mm length) |

| Scraper height | 65 ±1mm |

| Thickness of scraper blade | 0.25mm Diamond like carbon coating |

| Print Mode | Single or double scraper printing |

| Demoulding length | 0.02 mm-12 mm |

| Printing speed | 0-200 mm/s |

| Printing pressure | 0.5kg-10Kg |

| Printing schedule | ± 200mm (from the center) |

| Cleaning parameters | |

| Cleaning method | 1. Drip shower cleaning system; 2. Dry, wet, and vacuum modes |

| Cleaning and wiping board length | 380mm (optional 300mm, 450mm, 500mm) |

| Images parameter | |

| Film and Television Perspective | 8mm x 6mm |

| Platform adjustment scope | X:±5.0mm, Y:±7.0mm.θ:±2.0° |

| Reference point type | Standard shape reference points (see SMEMA standard), solder pads/openings |

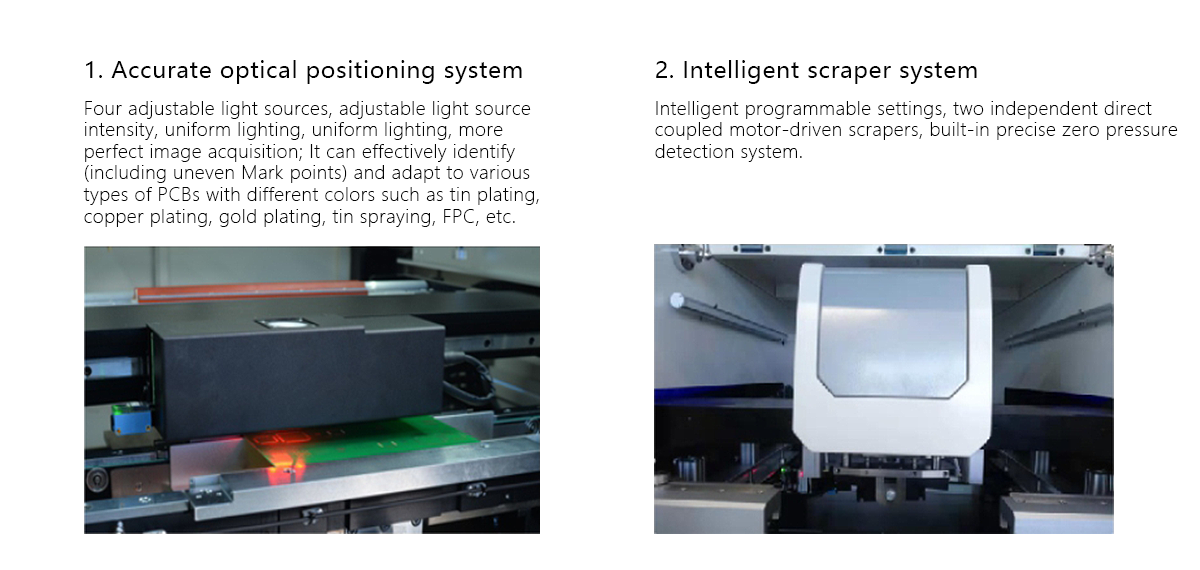

| Camera system | Individual camera, separate upward/downward imaging visual system |

| Performance parameter | |

| Repetitive accuracy of image calibration | ±10.0μm@6σ,Cpk≥2.0 |

| Printing accuracy | ±15.0μm@6σ.Cpk≥2.0 |

| Cycle time | <7s(Excluding printing and cleaning) |

| Change line time | <5mins |

| Equipment parameters | |

| Power requirements | AC110~220V 50/60HZ(Customization supported) |

| Compressed air requirements | 4~6Kg/cm2 |

| Operating system | Win7 |

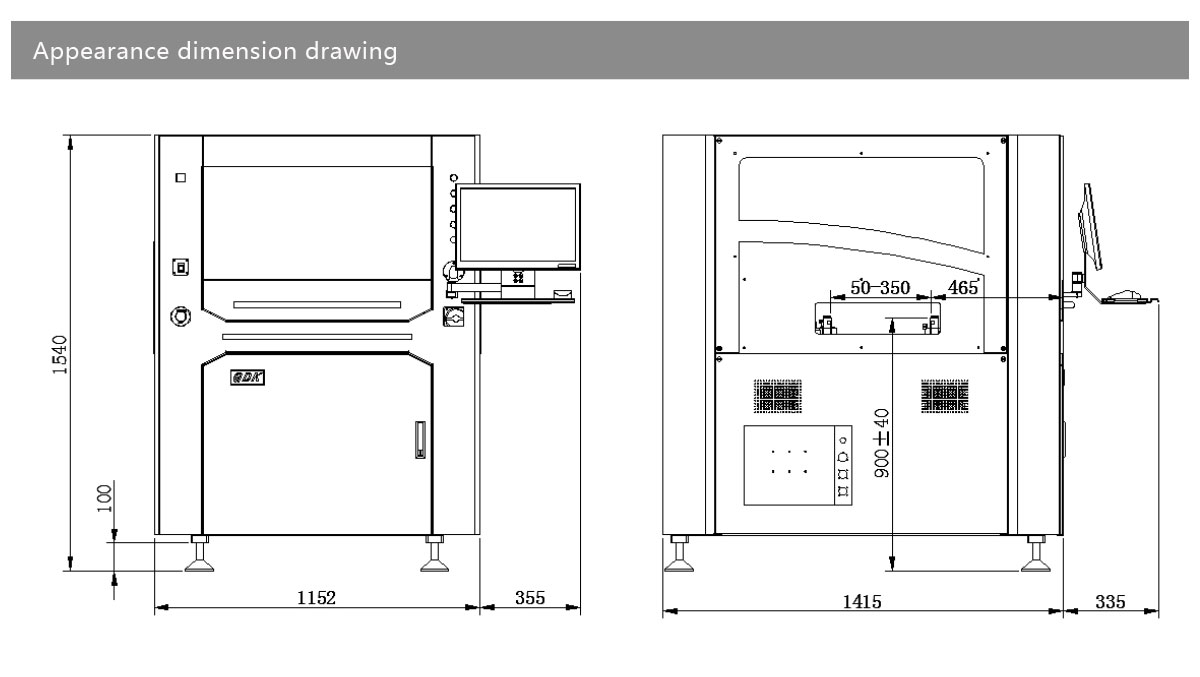

| Outline dimension | 1152mm (L) x1415mm (W) x1540mm (H) (excluding tri color lights, monitor, and keyboard) |

| Machine weight | About 1000Kg |

> Customization can be made according to customer needs.