Equipment Overview:

This equipment is used for cleaning the outer surface of various workpieces, such as wave soldering fixtures, reflow soldering trays, condensers, and cleaning the surface flux, oil stains, dust, etc. of machine components. The "spray cleaning machine" uses high-pressure spray cleaning, high-pressure spray bleaching, high-pressure air cutting, and high flow fan hot air drying techniques to ensure the cleaning effect of workpieces in a rotating basket.

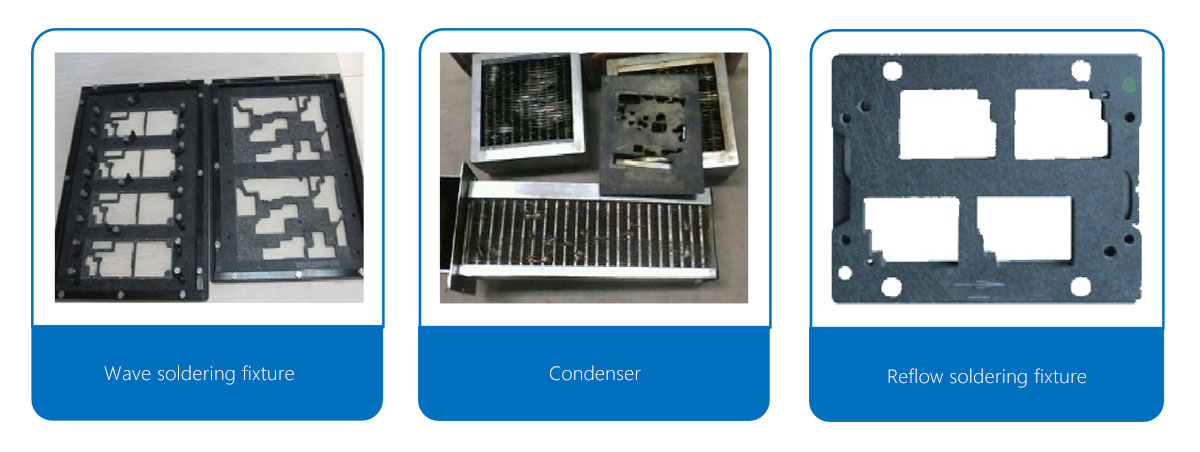

Cleaning object:

working principle:

1.The cleaning process generally uses water-based cleaning solution, which is added externally. Before cleaning, the liquid must be heated by a heater to enhance the cleaning ability. The stripped pollutants are filtered out through a filtering device, allowing the cleaning solution to be recycled and extending its lifespan. This type of cleaning solution is formulated without surfactants or solid substances, so that there will be no residue after the cleaning parts are dried. It will not have a shortened lifespan due to the permanent combination of surfactants and pollutants, which will gradually reduce the effective ingredients in the solution. It is safe and reliable after cleaning.

2.The rinsing process uses water as the rinsing solution, which is added through an external pipeline; Simply set the rinse time on the touch screen. During rinsing, use the pressure generated by the water pump to impact and peel off the liquid residue on the fixture surface. The stripped pollutants are filtered out through a filtering device to avoid secondary pollution and ensure cleaning effectiveness.

3.The drying process is to use the high temperature generated by the heater and the circulating hot air to dry the small amount of water and moisture carried out by the rinsing tank of the fixture. During the process of wind flow, the heater rapidly heats the wind, and when the hot air blows towards the fixture surface, the circulating hot air accelerates the evaporation of the liquid. Remove moisture and water vapor from the fixture to achieve the purpose of drying.

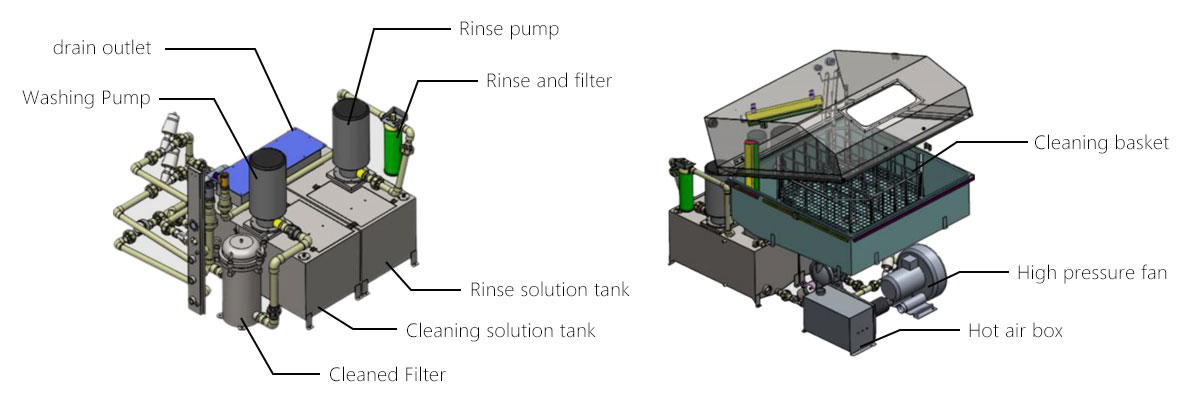

Product Structure and Function:

The equipment mainly consists of a rack, a spray cleaning system, a spray rinsing system, a cleaning basket rotating mechanism, a cleaning solution tank, a rinsing solution tank, an electric heating air system, a water circulation system, a drainage system, an equipment cover, a high-pressure air cutting system, and an electrical control box.

1.Cleaning system

During cleaning, nozzles are arranged on the top, bottom, and sides of the rotating cleaning basket. While the workpiece rotates, all cleaning nozzles spray high-pressure cleaning solution to scan and clean the workpiece in all directions. The cleaned cleaning solution flows back to the cleaning solution tank for circulation filtration and heating.

2.Rinse system

During rinsing, nozzles are arranged on the upper, lower, and side surfaces of the rotating cleaning basket. While the workpiece rotates, all rinsing nozzles spray high-pressure pure water to scan and rinse the workpiece in all directions. The residual cleaning solution after rinsing is thoroughly rinsed off, and the rinsing solution flows back to the cleaning solution tank for circulation filtration and heating.

3.Storage tank

The cleaning solution tank is used to recycle and store cleaning solution for filtration. There are two stainless steel primary filter screens at the outlet of the cleaning solution tank to protect the cleaning pump, which is then filtered through a 10um filter.

4.Rotating basket device

The rotating basket is driven by a variable frequency motor through a chain mechanism, ensuring low noise and smooth rotation of the working basket.

Product features:

01. Add automatic liquid dispensing and rinsing functions

Compared to similar products from other brands, this equipment has added automatic liquid addition and discharge, rinsing, and mechanical defoaming devices. Make cleaning more thorough.

02. Dual pump dual pipeline system

In response to liquid loss, this equipment adopts a separate drainage system for cleaning and rinsing pumps, which eliminates the phenomenon of mixing cleaning and rinsing liquids and greatly reduces liquid loss compared to similar equipment.

03. Washable filter element

We have specially customized a washable stainless steel filter element to address the issue of excessive impurities on the fixture. Compared to traditional disposable filters, it significantly reduces the cost of consumables.

04. Pipeline materials

Imported PPH pipeline material, using hot melt welding, can withstand strong acids and alkalis, ensuring long-term use without leakage. Compared to its peers, stainless steel pipeline maintenance, upkeep, and replacement are more convenient and simple.

05. Safety door device

Safety door anti slip device, basket torque alarm device, avoiding safety hazards.

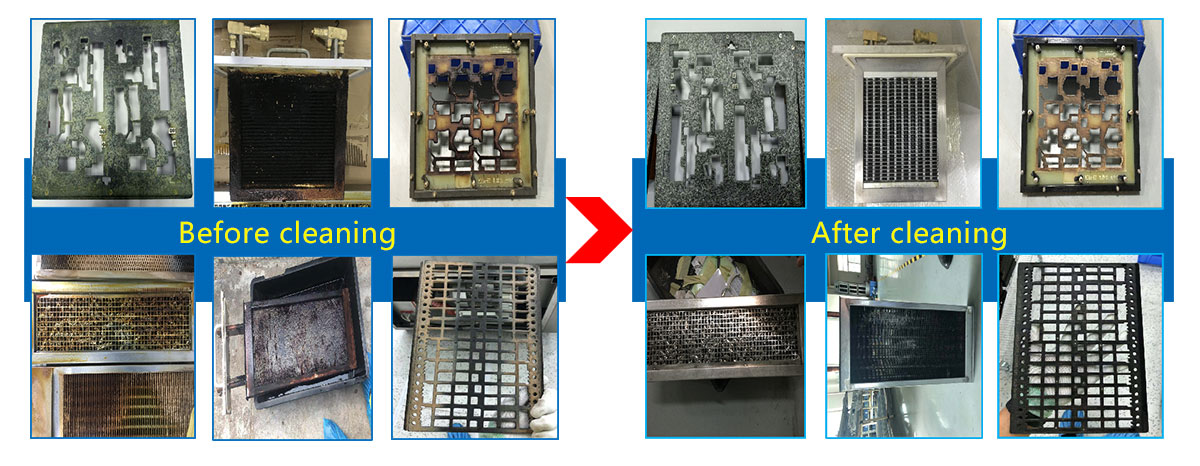

Comparison of Cleaning Examples:

Product parameters:

| Machine dimensions (mm) | L1830*W1450*H1500 |

| Voltage | 110~380V 50/60HZ (Customization supported) |

| Maximum power | 27KW |

| Rated current | 30A |

| Gas source | 0.4-0.6Mpa |

| Water source | 0.1-0.3Mpa |

| Exhaust vent | Ø125mm |

| Working basket diameter | 1000mm |

| Maximum height of workpiece | 480mm |

| Work basket load | 100 KG |

| Pressure Range | 3-8 KG |

| Tank capacity | 60L * 2, it is recommended to add 50L (add cleaning agent to the cleaning box, add water to the rinsing box) |

| Spray pressure | 3-6KG |

| The whole machine is heavy in weight | 480KG |

> Customization can be made according to customer needs.